Marine shipping has to decarbonize and hype is strong around sexy but foolish solutions

· 16 min read

Marine shipping is considered to be a hard decarbonization target, but that actually isn’t true. It’s a small fraction of ground transportation in terms of fossil fuel consumption, a lot of it is pretty short haul, and there are obvious wedges. But that doesn’t mean that there isn’t a lot of hype and hopium in the space.

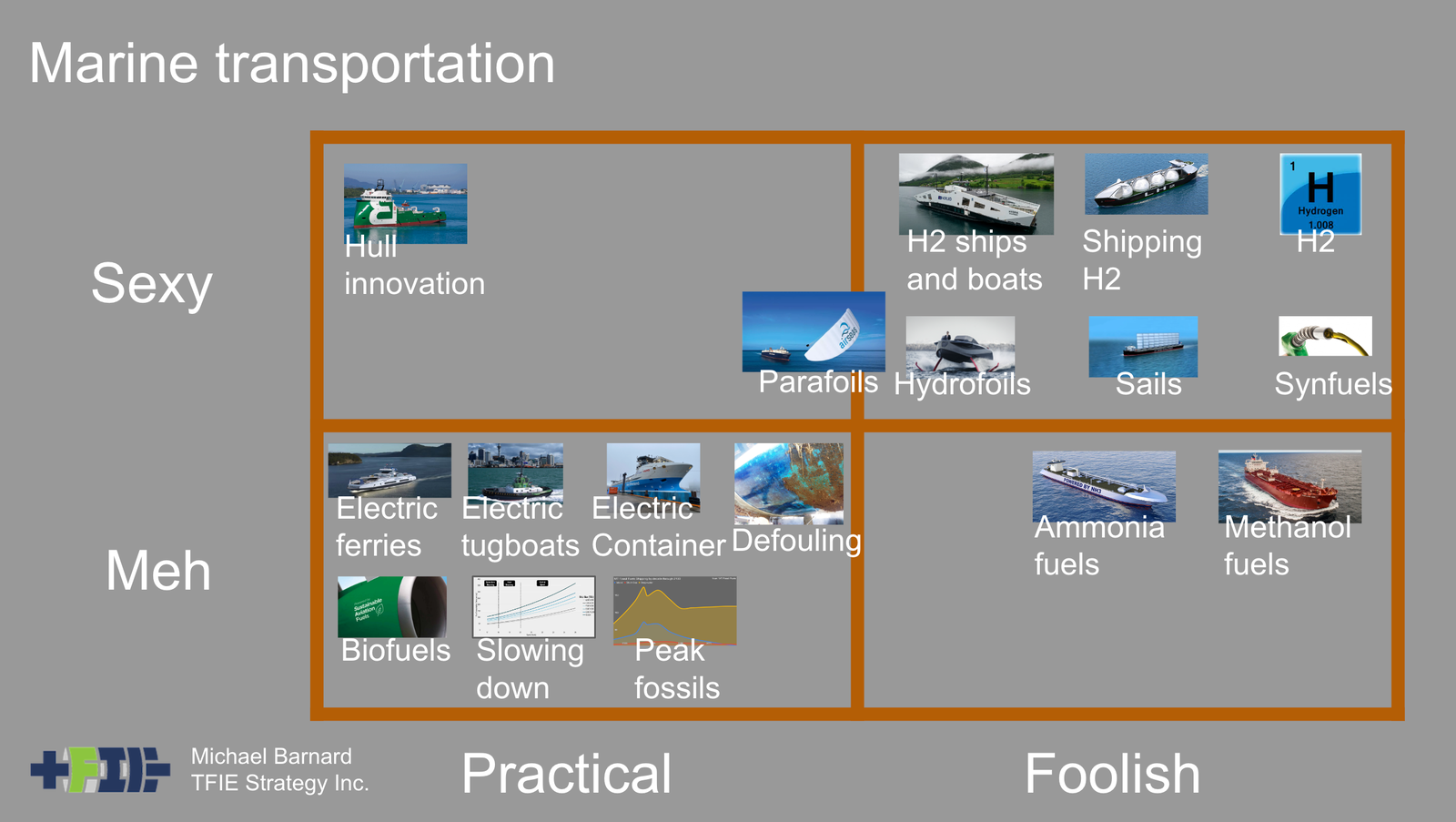

And so, a walk through a simple taxonomy of various marine transportation overhyped fluff and practical but often ignored solutions. The model is straightforward, a quadrant chart with sexy and meh as the vertical choices and practical and foolish as the horizontal ones.

What defines sexy? Lots of press. Frequent headlines. Gushing talking heads who should know better. Promises of hyperbolic deployment and profits. SPACs or ICOs. VCs. Glistening PhotoShop renders. Curves. Lots of fanbois and fangrrrls who take every opportunity to rant about its wonders.

Meh? Few media headlines. Business as usual. Stuck in narrow and industry-specific journals. Lots and lots of numbers, and often not a lot of hype. Sometimes lots of institutional investment.

Practical? Lots of deployment. Lots of deals. Lots of straightforward growth. Economically viable. Don’t assume the laws of physics are mutable. Don’t assume human nature will magically change.

Foolish? Ignore laws of thermodynamics. Ignore better alternatives. Ignore tiny market potential. Ignore the history of failures of exactly the same thing. Ignore human nature. Ignore denominators. Delivery always fading into the future. PowerPoint and PhotoShop, not production.

Let’s walk through the chart, starting with what’s sexy and practical.

Over the past few decades, two big changes occurred in ships’ hulls. One of them was that ships got longer. The longer the waterline, the more efficient the ships are at slipping through it. That’s enabled container ships especially to sprint across oceans at 24 knots, satisfying consumer needs for fast fashion and the latest toys.

The second was the inclusion of bulbous bows on ships, extending the waterline without lengthening the hull. These vaguely torpedo-shaped extensions at the water line provide 12% to 15% efficiency increases for oil tankers, passenger liners, and container ships, and they are still being retrofitted to older hulls today.

But hull innovation hasn’t ended. In recent years, the Ulstein X-Bow has been appearing on ships globally. This is a fairly radical ship design transformation, brainstormed by the Norwegian ship-building firm Ulstein in the early 2000s. It inverts the bow, putting the point at water level and having smooth sides moving up and away from that point. The bow slices through waves instead of bashing through them or riding up and over them, increasing efficiency and speed in heavier seas and smoothing the ride. It lengthens the water line, increasing the hull speed without increasing overall length, allowing for more efficient operation. It reduces white water over the bows by pushing more green water higher and around the high bow. And bow thrusters can be further forward as well, enhancing maneuverability.

There’s more. Container ships are starting to have high aerodynamic shields added to the front of the ship to smooth airflow around the containers, turning the ship from a 24 knot brick into a sleeker profile with up to 4% fuel savings.

Also in the sexy and practical quadrant are parafoils sailing from the bow of ships. They work on specific routes, and they launch, fly and furl automatically. Various companies have introduced and tried them. The challenge is the same as in building efficiency, in that ship builders and owners bear the capital costs, while ship operators are frequently different organizations leasing the ships and gaining the economic benefits. My projection is that on routes where they are applicable, they can provide 10% efficiency gains.

But sharp eyes will notice that parafoils verge into the sexy but foolish range. That’s mostly because their benefits are overstated and, having assessed large fabric power kite autolaunching and autofurling a few years ago, I know that these processes are susceptible to occasional failures which will require crew intervention and shoreside repairs. But that’s a minor downside compared to the rest of the sexy but foolish quadrant.

Keeping with the wind energy theme for a minute longer, hard sails and Magnus effect rotors on ships don’t make much sense. There is no ability to add them to container ships, so they are restricted to bulk shipping. However, due to strains on the hull, they’d have to be either heavily buttressed internally or have the hulls built from scratch for them. And they’d require keels extending down far enough that they couldn’t get through the Suez or Panama Canals and couldn’t enter most ports. Finally, they’d interfere with loading and offloading cargo.

While I love wind energy at most scales, sails on container ships except for parafoils on the bows don’t make any sense. In a recent discussion with Wind Support NYC, an organization quixotically devoted to sails on ships, we discussed the example that they had in mind, a tiny 120 container ship being built to take spices from, if memory serves, Madagascar to Europe. Given that modern container ships carry 24,000 TEUs, this didn’t seem particularly relevant. But sails are romantic, and article after article gets published about them.

Pride of place in this quadrant is all things hydrogen. Oil and gas firms would really love hydrogen and its synthetic derivatives to be the new transportation fuel of choice. LNG shipping firms and ship builders would really like their business models to not disappear when we stop shipping molecules for energy across the oceans. But these are faint hopes.

Hydrogen used directly as a shipping fuel runs into a bunch of headwinds. While the gas is energy dense by mass, it’s the opposite by volume. Solving that problem requires compressing it at 750 atmospheres, which is what fuel cell ground vehicles do to get 5 kilograms of the gas into the 142 liters of the tank. The energy density of even highly compressed hydrogen is far less than that of bunker fuel. The other option is to lower its temperature until it turns into a liquid, a multi-step process that has to get the gas down to 20° above absolute zero. Even then its energy density by volume is much lower than bunker fuel, and the tanks have to be bulbous. Dockside bunkering facilities that can chill hydrogen to 20° Kelvin aren’t going to be a thing.

Next is cost. There’s a lot of hype about green hydrogen getting down to a dollar a kilogram or so, about what it costs to make it from natural gas if we don’t bother to capture the CO2. But that’s specious nonsense as the price of electricity plus capex for electrolyzer plus balance of plant plus liquification facilities drive the cost per kilogram up to closer to $10 US dockside. That’s undoubtedly a big part of the reason why Equinor, Eviny and Air Liquide pulled the plug on their Norwegian green liquid hydrogen fueling plan recently because no one is going to pay those big multiples of bunkering prices.

Also facing this problem are synthetic bunker fuels made from green hydrogen. Making green hydrogen won’t be cheap due to the combination of opex and capex amortization, and then making any green fuel from them requires additional steps and energy which drives the price up further.

So why is green hydrogen being pushed so hard while being so unfit for purpose? There are multiple reasons. The biggest one is that the fossil fuel industry is looking at the entire marine shipping industry stopping buying their products, along with every other industry in the world. They have to make green hydrogen for energy the ‘solution’, because they know that there’s no way to make remotely enough green hydrogen to replace fossil fuels, so blue hydrogen would have to be used. Without blue hydrogen, the value of fossil fuel reserves collapses.

As Michael Liebreich says, the fossil fuel industry can’t lose by pushing green hydrogen. Either they delay real decarbonization by a decade and get to reap climate-damaging profits for another few years, or governments force green hydrogen at enormous expense upon society and blue hydrogen preserves, or even increases, the industry's revenue and profits. That’s not a reason for the rest of the world to go along with the idea.

The other challenge which leads to hydrogen and synthetic fuels being taken remotely seriously is that maritime concerns burn fuels today, and so their question is “what low-carbon fuels will I burn tomorrow?”, not “where will I get energy for propulsion from?” This is a standard cognitive problem faced by most people and organizations burning fossil fuels today, so it’s not like they are alone in it, but it’s still a problem.

Last in this quadrant are hydrofoils for things bigger than a kitesurfer. I do love hydrofoils, love watching hydrofoil SUP surfing and would love to play with an electric hydrofoil surfboard. But when you start putting them on bigger ships, problems abound immediately. The biggest is that they keep running into anything in the water and potentially breaking. There are a lot of shipping containers floating just below the surface in the waters of the world and at normal ship speeds, there’s a bit of clanging as they scrape along the hull and nothing else. Similarly, the number of massive lengths of cut timber in the oceans is huge as well. Hydrofoils don’t fare well running into solid objects. Of course, like keels for sails, they increase draught and so aren’t fit for larger ships that have to get through canals or ports. But they certainly are delightful to watch on tiny vessels as they slice gracefully through the water, at least until they hit something below the surface and snap off.

And so, onto foolish and meh. Ammonia and methanol are bulk commodities today. They are even shipped in tankers across the oceans. And they are liquids at temperatures that ships operate at, which is an advantage. Obviously making them from green hydrogen has the same cost disadvantages as with any synthetic fuel, so they are not likely to be considered seriously if cheaper low-carbon alternatives are available, which there are.

However, both green methanol and green ammonia face further challenges. Methanol’s energy density is 45% that of bunker fuel, so it would require not only tanks 2.2 times the size of the ship, but bunkering facilities in ports 2.2 times the size of current bunkering for the duration of the transition. Ammonia has an even lower energy density. Most ports are already space-constrained, and if they want to expand anything, it’s space for containers, so eating a lot of space for low-density fuels isn’t something that they’ll be particularly interested in. If made from green hydrogen, both will be vastly more expensive than the alternatives.

And both methanol and ammonia have greater health risks than bunker fuel. Getting methanol on your skin and not washing it off can lead to organ failure, so that’s a concern, although a manageable one. Ammonia, on the other hand, is toxic when its fumes are inhaled, and when it mixes with water, it turns into a highly corrosive gas, ammonium hydroxide, which if inhaled basically dissolves the lungs. And then it turns into another gas which is just bad for human health after that.

A Netherlands health official responsible for three ports and several communities in the country recently pointed this out, saying that an ammonia bunkering spill in a port could easily kill 80,000 citizens, and asked what in the world people were thinking. The Global Center for Marine Decarbonization in Singapore is running a project to attempt to address ammonia bunkering, but as I said to the CEO Lynn Loo a few weeks ago, that effort’s greatest value is that it will fail to address it and a concrete assessment can be pointed at to put a stake in the bad idea’s heart.

Of course, the global methanol industry is salivating at the idea of methanol becoming a shipping fuel despite the clear problems. Methanex, the 800-pound gorilla in the methanol world, recently had its subsidiary Waterfront Shipping run a purportedly carbon-neutral methanol-powered ship across the Atlantic. The problem there was that the ‘carbon-neutral’ methanol was 95% made from unabated natural gas with 5% of biomethane added to the process that they claimed would otherwise have been vented to the atmosphere. This is, of course, specious greenwashing.

In my projection of marine decarbonization, the burnable fuels still required after all inland shipping and two-thirds of near-shore shipping have been electrified with batteries would require a tripling of the 170 million tons of methanol manufactured annually. You can see why Methanex and the rest of the methanol industry are delighted with the idea. What’s less clear is why Maersk thinks it’s remotely sensible.

As for shipping hydrogen made in distant and sunny lands to Europe or Japan as a replacement for LNG, that would result in, at minimum, five times the cost per unit of energy delivered. Along with the problems of liquification requiring massive amounts of energy, LH2 ships would be boiling off 2% to 3% of the hydrogen every day, with no ability to reliquify it on ships. The theory is that boil-off would be used to power the engines, just as LNG boil-off of 1% to 1.5% is used today. But with no customers willing to pay for energy that expensive and the ease of making hydrogen at the point of consumption for industrial processes using electricity, no hydrogen shipping will emerge.

And so, on to the practical but meh quadrant, the one where most of the real solutions are, the one where most of the money will actually be spent and the one the maritime industry should be steaming toward as rapidly as possible.

As noted earlier, an enormous amount of shipping can be electrified with batteries, and as a result, it will be. Batteries driving electric motors are much more efficient than even the most efficient marine engine today, not to mention the vastly lower emissions energy source to propeller. Containerizing batteries is already a normal part of our economy with companies like Tesla and Wärtsilä delivering pre-packaged, ready-to-plug-in batteries to the grid and behind-the-meter storage customers globally. Trains will be using containerized batteries as well to bridge hard-to-electrify segments of existing rail systems such as tunnels where catenary lines can’t be installed, so trains and ships swapping batteries charged in transshipment ports is an obvious pathway.

All inland and two-thirds of short-sea shipping will be running on batteries in my projection. Energy density and cost curves are plummeting, and container ships already plug in freezer containers today, so plugging in bigger cables to draw energy is trivial. Smaller craft like tugs and ferries will simply plug in to charge at docks.

The number and size of electrified vessels is leaping upwards annually. A 1,300 passenger cruise ship is already doing Three Gorges day tours with 7.5 MWh of built-in battery. Electric inland and short-sea container ships are already being tested on the Yangtze and being prepared for delivery to Europe. Absurd numbers of ferries and tugs are already running on batteries.

Big advantages here as all of the air pollution and noise from inland and near-shore shipping goes away with the engines and fuel.

Another excellent wedge is efficiency measures. The big one is just slowing down. Container ships sprinting across the ocean at 24 knots can save enormous amounts of fuel by crossing at 17 knots. Fuel efficiency decreases more and more with each knot of speed increase, so 30% savings are easy to achieve.

But defouling technologies are big as well and have taken great strides. At one point, it was considered reasonable to slather toxic coatings over hulls, but that’s gone mostly by the wayside as it became obvious how destructive they were to marine ecosystems. Studies assert that roughly 50% of ships at any time globally are suffering significant efficiency losses due to fouling. But now two innovations are reducing fouling which can have massive efficiency implications for ships.

The first is robotic defouling rigs in ports that replace human divers. Much greater efficiency and ability to work around the clock and much cheaper operations, so they can be used more. More ships defouled more often and hence less fuel use per ton.

But what if fouling never occurred? That’s what ultrasonic anti-fouling add-ons, available from multiple vendors, do. Transducers are attached to the hull, powered by ship auxiliary electricity, and emit high-energy noise above the level of human hearing. This prevents even the tiniest waterborne plant and animal life from adhering to the hulls, are unlikely to cause issues further from the hull, and sip at a fraction of the energy that they save.

Even with electrification, slowing down and no fouling, 16,000 tons of bunker fuel pushing big ships across the Pacific isn’t going to be replaced by batteries this century. Other things will be required. However, the problem isn’t nearly as big as most assume.

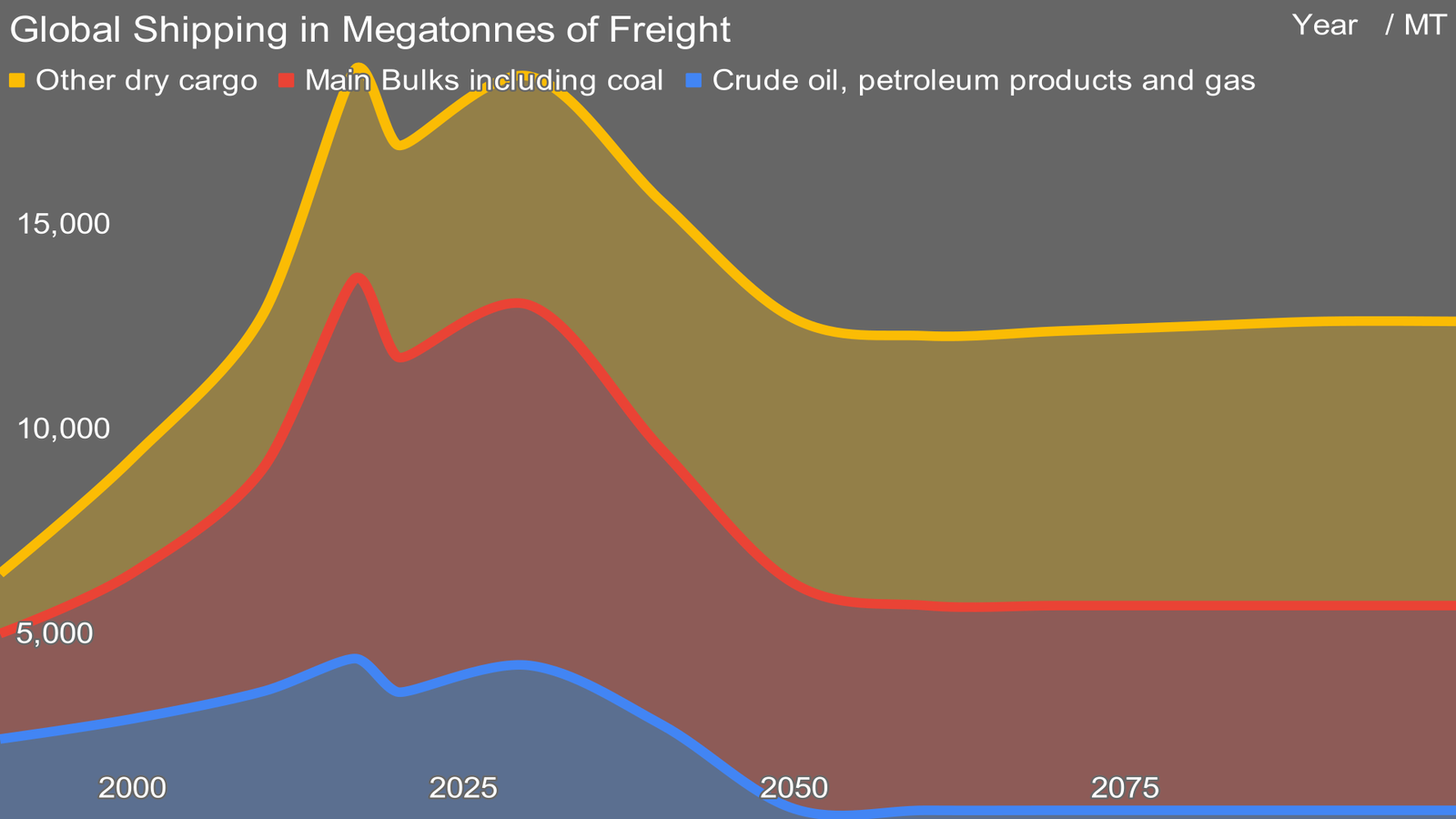

Transoceanic shipping is going to decline quite a bit in the coming decades in my projection. Why? Because so much of it is coal, oil and gas. 40% of bulk deepwater shipping is fossil fuels. That has to go away, and as the 80% of fuels used for ground transportation will disappear with electrification, and coal and natural gas generation will disappear with renewables, bulk shipping of them will vanish.

And another 15% of deep water shipping is for raw iron ore, usually steaming toward the same ports as coal, where both are shoveled into blast and open hearth furnaces to make steel. However, that’s going to change with the combination of rapidly increasing scrap steel processing in electric steel minimills as China finishes its massive infrastructure build out, and direct reduction of iron ore with hydrogen or electricity, likely closer to the mine with only iron pellets, steel ingots and similar processed products being shipped in containers instead.

That’s 55% of bulk shipping which is going to decline to a fraction of that tonnage over the coming decades. The growth in container shipping won’t counteract that volume of decline.

And that bulk shipping won’t be replaced with other molecules for energy for the most part. Remember, all ground transportation electrifies, so no molecules are needed. All natural gas and coal generation is replaced by renewables, so no liquid hydrogen is required.

But still, liquid fuels are required, so what will they be? Biofuels, and in my opinion, biodiesel. The process is straightforward. Take waste biomass, ferment it like beer a bit, distill it like alcohol, then upgrade it a bit to biodiesel. The first beer was brewed 8,000 years ago. The first alcohol was distilled 6,000 years ago. The first biodiesel was made by Rudolf Diesel in 1890. One pathway for biofuels of about seven, stalk cellulosic biofuels which leave the ear for animal or human feed and the stalk for fuel, has sufficient feedstock from current corn, wheat and rice to fuel all aviation and marine shipping that can’t be directly electrified.

Biodiesel has significant advantages as a bunker replacement. It’s cheaper than synthetic fuels by a large margin. It has a slightly higher energy density than bunker fuel because it has less excess random stuff in it. It burns cleaner too, although that matters less as it will mostly be burned a long way from land. It can be mixed with normal bunker fuel in existing port bunkering facilities and still deliver climate benefits.

Agriculture will be decarbonizing over the coming decades with green ammonia, reductions in ammonia usage due to agrigenetics, precision agriculture and low-tillage agriculture processes, and just moving the remaining subsistence farmers off the land and into more productive work. As a result, biofuels which are already pretty virtuous compared to fossil fuels will plummet in CO2 emissions, getting down to zero in 30 or 40 years.

The result of mostly the practical but meh wedges in marine shipping is a massive reduction in CO2 emissions from this transportation segment over the coming decades. As noted at the beginning of the article, this isn’t nearly as hard to address as many people believe.

illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.

illuminem briefings

Mobility Tech · Green Tech

illuminem briefings

Corporate Governance · Green Tech

illuminem briefings

Mobility Tech · Shared Mobility

The Wall Street Journal

Green Tech · Mobility Tech

The Guardian

Electric Vehicles · Public Governance

BBC

Mobility Tech · Labor Rights