Redefining Industrial Heat: The Crucial Role of Thermal Energy Storage in a Decarbonized Future

· 10 min read

Our civilization has always been closely tied to fire. Since humans learned to harness fire around 40,000 years ago, heat has become one of our primary needs and a precondition for modernity.

We need heat to keep warm and to produce almost everything we consume.

Heat is the foundation of any manufacturing process—cooking, sterilizing, metal melting—and meets our daily requirements, from fertilizers to animal feed, steel and plastic for automobiles, and cement for buildings and structures.

Imagine traveling back in time to the middle of the 18th century, when the world was about to undergo a revolutionary change known in all textbooks as the Industrial Revolution. This period, powered by the non-human strength of fossil fuels, gave industries all around the world productivity and efficiency never seen before.

Coal was powering steam engines and machinery in textile mills, ironworks, and beyond. Thomas Newcomen's atmospheric engine in 1712 laid the foundation, but it was James Watt's 1769 steam engine that truly set the stage for coal's reign (which also initiated the black foggy London impression).

Fast forward to the 20th century, and oil-fired boilers enter the scene, offering superior energy density, easy transportation, and storage. Then, along came natural gas boilers, boasting “cleaner-burning” properties and even greater efficiency.

Now, 250 years after Watt's groundbreaking invention, it's time for another revolutionary shift: embracing the power of renewable electricity as the ultimate fuel for steam. And here's why...

Energy-related emissions are a major concern, and 45% of them come from heat. Heating and cooling applications account for over 50% of global energy consumption in all sectors. Industrial heat demand, which makes up 40% of the total heat demand, includes uses ranging from low-grade heating to high-temperature applications over 1,500°C.

The industrial sector depends heavily on fossil fuels, with most industrial heat demands involving direct hot air or steam for processes like drying, calcination, or chemical reactions. Fossil fuels, including oil/diesel, coal, and gas-fired boilers, provide almost all industrial heat around the clock.

To achieve net-zero emissions, decarbonizing industrial heat is essential and it will contribute to around 20% of the effort. How can we address one-fifth of the net-zero target?

In November 2022, the Long Duration Energy Storage Council published a report on achieving Net-Zero Heat (NZH), emphasizing the importance of Thermal Energy Storage technologies.

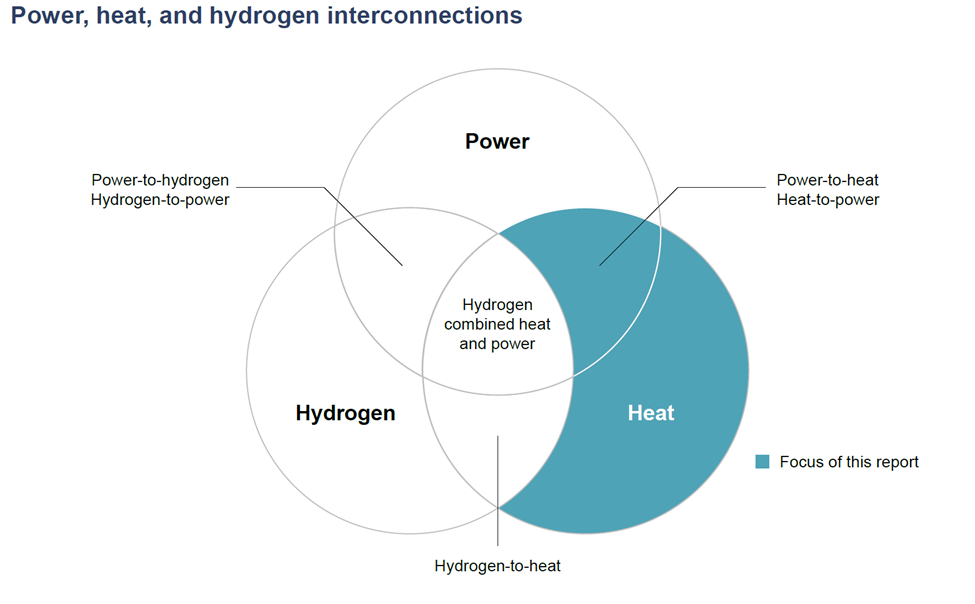

The key strategy is to interconnect different energy types. To decarbonize industrial heat, consider using renewable power (in the short, medium, and long term) and green hydrogen (in the long term).

Since green hydrogen comes from renewables, it's more efficient to directly convert green power into heat through the joule effect, resulting in conversion efficiencies close to 100%.

Electro-technical engineers often argue for the superiority of electricity, noting that energy conversions can result in losses. However, industrial best practices based on the purity of conversion rates must evolve if we want to move beyond the anchor mindset of burning fossil fuels for heat production (i.e. accepting some auxiliary power needed for the conversion from power to heat).

The NZH study predicts that the overlap between power and heat will significantly increase in the next future, with TES reaching the efficiency peak after the year 2030[1].

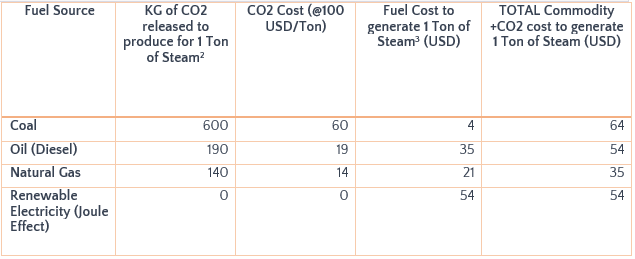

From a different angle, collecting basic info on energy conversion rates and applying to normalized costs, while renewable energy sources have a clear advantage in terms of CO2 emissions, the cost of competing with gas remains a challenge:

As renewable energy sources continue to grow globally, electricity prices are likely to decrease significantly or even become negligible in certain areas or timeframes with frequent curtailments.

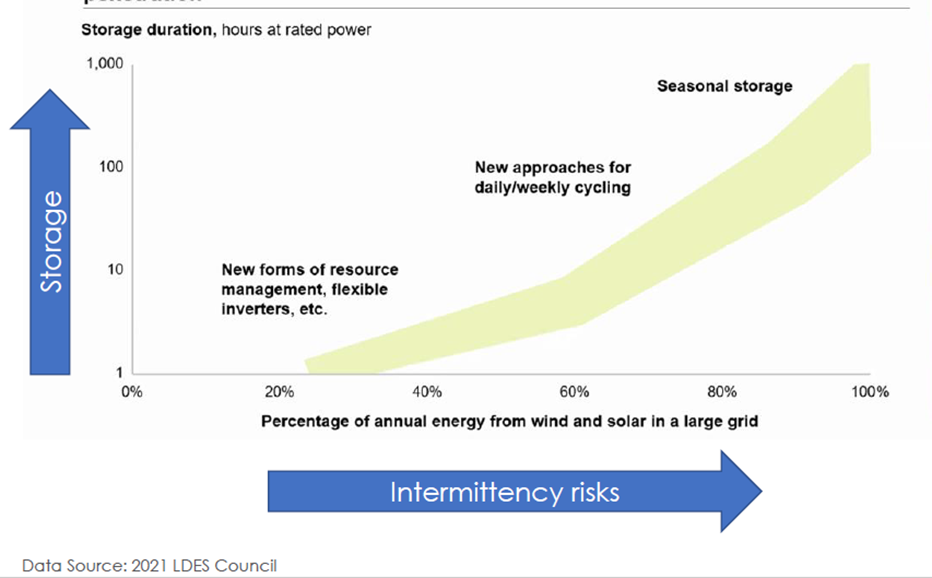

However, when renewable energy penetration in an energy system exceeds 50%, extensive storage capacity is required to maintain grid stability and flexibility:

The LDES 2021 report shows that the necessary storage duration will shift from hours to days or weeks when the 50% threshold is reached.

Although lithium-ion batteries are often seen as the ideal solution for addressing intermittency issues, they have inherent limitations and concerns:

Vis-a-vis heat decarbonization, Lithium-Ion batteries simply do not produce heat.

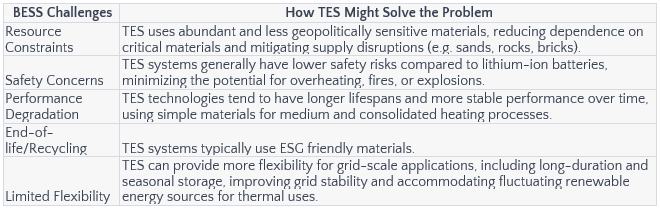

This highlights the need for an alternative energy storage technology that can either work independently or alongside battery energy storage systems (BESS) to address the mentioned challenges.

To decarbonize industrial heat processes, industrial players can follow these steps:

Let’s see why the thermal storage technologies will play a big role.

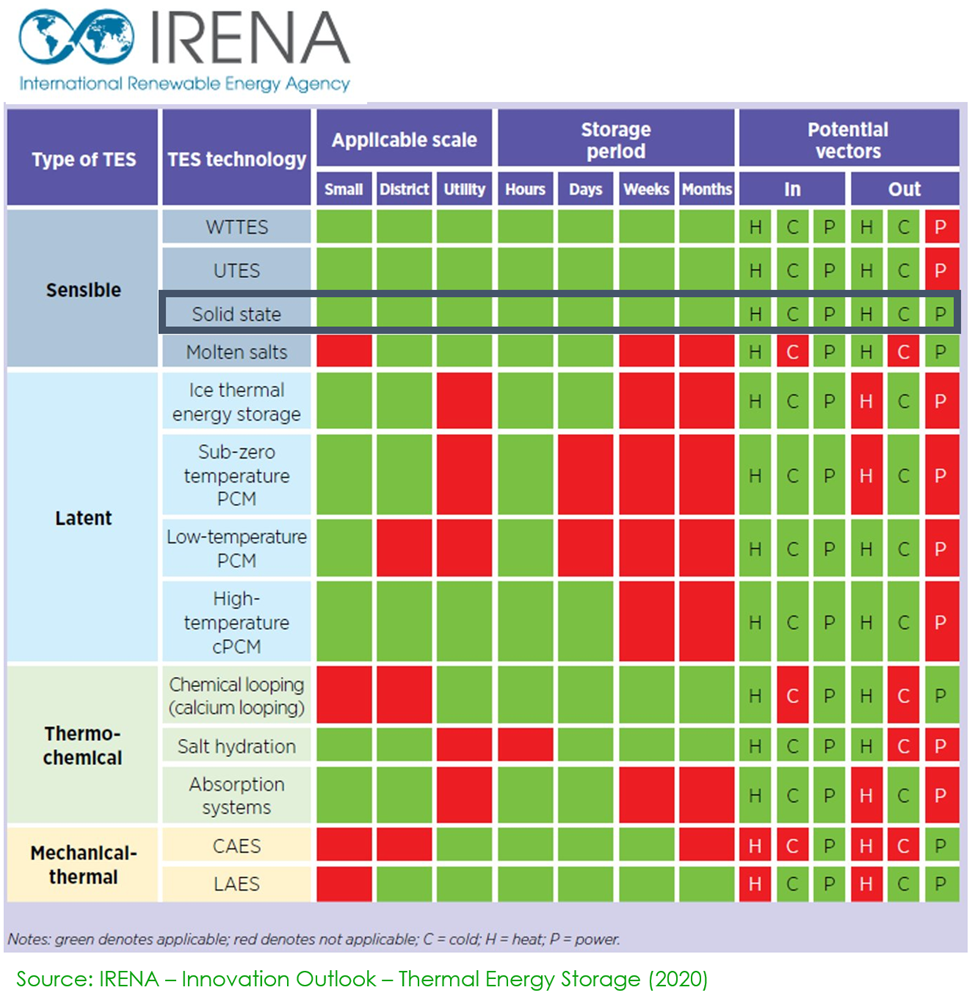

Thermal energy storage (TES) is a flexible technology with three main types: sensible, latent, and thermochemical heat storage. These types store thermal energy by raising the temperature of a solid or liquid, changing a material's phase, or utilizing chemical reactions.

Various materials can be utilized within each category, resulting in diverse operating temperatures and durations. Consequently, the suitability of TES technologies varies depending on factors such as: temperature, scale, storage duration, heat form, footprint, and process integration.

The following charts from an IRENA study display a range of technologies, with solid-state TES being particularly promising:

TES technologies are capable of addressing a wide range of temperature and duration requirements for heat needs. Materials like sand, rocks, and water can cater to various temperature ranges and durations.

For instance, underground water systems can store heat from 0 to 100°C for months, while sand systems can store heat at up to 1,000°C. TES technologies are at different stages of development, with some being commercially tested, others in pilot setups, and some already deployed promising (i.e. at Magaldi we are developing a TES based on a multi-patented solid-state fluidized sand bed, which is reaching the commercial stage).

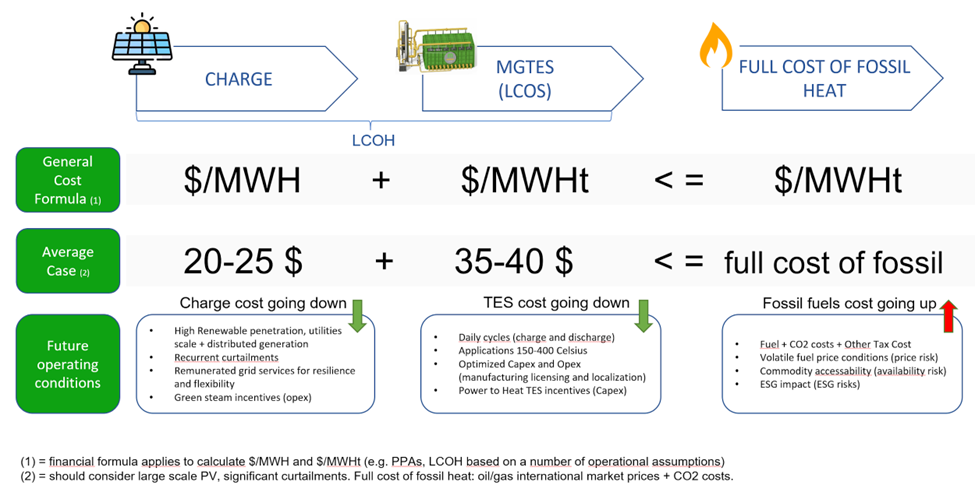

The chart below demonstrates a straightforward approach and trends for using Magaldi MGTES to replace heat generated by fossil fuels with renewable energy and thermal storage. The Levelized Cost of Heat (LCOH) break-even point is estimated to be around 60 USD/MWht:

The LCOH is the primary benchmarking metric used to assess the competitiveness of different steam decarbonization alternatives. The MGTES cost (LCOS) is predicted to be reduced by at least 50% in the next 5-7 years thanks to industrialization and large scale manufacturing.

In the LDES Net Zero Heat study it was found that the LCOH for an electric boiler with TES can be around USD 5 to 10 per MWh lower than for a gas boiler. This is mainly driven where lower capital expenditure (incentives) and potential differences in energy prices exist (i.e. charge TES when electricity prices are at the lowest during the 24h).

Now, going back to the constraints and BESS challenges, we could add that:

Thus, decarbonization using electrification and thermal energy storage (TES) is becoming financially viable. TES is more affordable than batteries and hydrogen options because of lower initial costs and higher efficiency throughout its lifespan, offering several strategic benefits.

But, what are the main obstacles TES must overcome to become a mainstream solution for the energy transition?

There is limited awareness and recognition among the industrial sector and energy managers about the potential of TES.

Additionally, TES technology providers need to address specific challenges:

Having said that, there are a number of ways stakeholders can support TES adoption:

Business leaders:

Policymakers:

Investors:

By broadly adopting Thermal Energy Storage (TES) technology, the grid can be more flexible, energy costs can be reduced, and renewable energy resources can be utilized more efficiently, reducing curtailments.

TES contributes to a more stable and reliable energy system by storing excess electricity generated during low-demand periods and releasing it when necessary in form of steam or hot air.

Furthermore, TES plays a crucial role in the decarbonization of industries and the global energy sector, as it facilitates the transition away from fossil fuels and towards a more sustainable, low-carbon future, up to 20% of the total current global footprint.

Having viewed 250 years of history through the lens of the industrial revolution, we find ourselves at a pivotal point in time. TES technology has the potential to allow industries to move away from their passive reliance on fossil fuels and embrace a modern, more efficient renewable energy mindset for any industrial thermal need.

[1] Other Long Duration Energy Storage technologies (i.e. chemical, gravitational, electrochemical) will navigate between 55-60% roundtrip efficiency (power to power)

[2] Source: https://ourworldindata.org/emissions-by-fuel, conversion rates, for commodities average values

[3]Coal = 100 Kg*40 USD/Tonn; Diesel = 70 Kg*500 USD/Tonn; Gas = 70 m3*0.3 USD /m3; Renewable = 0.9 MWh*60 USD /MWh. Market data will change however, renewable energy cost is predicted to decrease

illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.

Vincent Ruinet

Power Grid · Power & Utilities

Olaoluwa John Adeleke

Human Rights · Environmental Rights

illuminem briefings

Power Grid · Power & Utilities

The Korea Herald

Energy Storage · Battery

Automation World

Battery · Energy Storage

H2-View

Hydrogen · Energy Storage