· 5 min read

Despite having been around for 30 years, never before has eco-design become such a popular philosophy of design. Companies are either being praised or criticised if they present eco-design labelled offers - it is either a good push in the right direction towards a more sustainable future, or it is greenwashing. As business leaders, it is important to navigate among these noises: what are the limitations of eco-design, as used today? Will it bring a differentiation factor or will it drive up the production cost?

Eco-design as used today is counterproductive

Let’s look at the case of a multinational food and beverage company, one of our clients. As plastics and plastic packagings for food and beverages are under scrutiny in Europe, the Strategy and Innovation team started to explore different packaging materials. One of the ideas was to use aluminium - which is recyclable and gives a luxurious touch to the product. They spent 12 months conducting studies and surveys to choose the perfect test subject, and then another 12 months to replace the plastic packaging with a super thin, recyclable aluminium one.

However, aluminium packaging is too expensive to produce. This drives up the production cost as well as the end customers' purchase price. The team, therefore, switched towards a design-to-cost approach: they spent another year studying the different product shapes that could minimise the production cost while keeping the new aluminium packaging. A new oval shape was proposed to replace the current cube shape, which drove the production cost of each unit down to 10%. Yet, this new shape caused another problem for stacking and storing. Logistics-wise, this is not optimal.

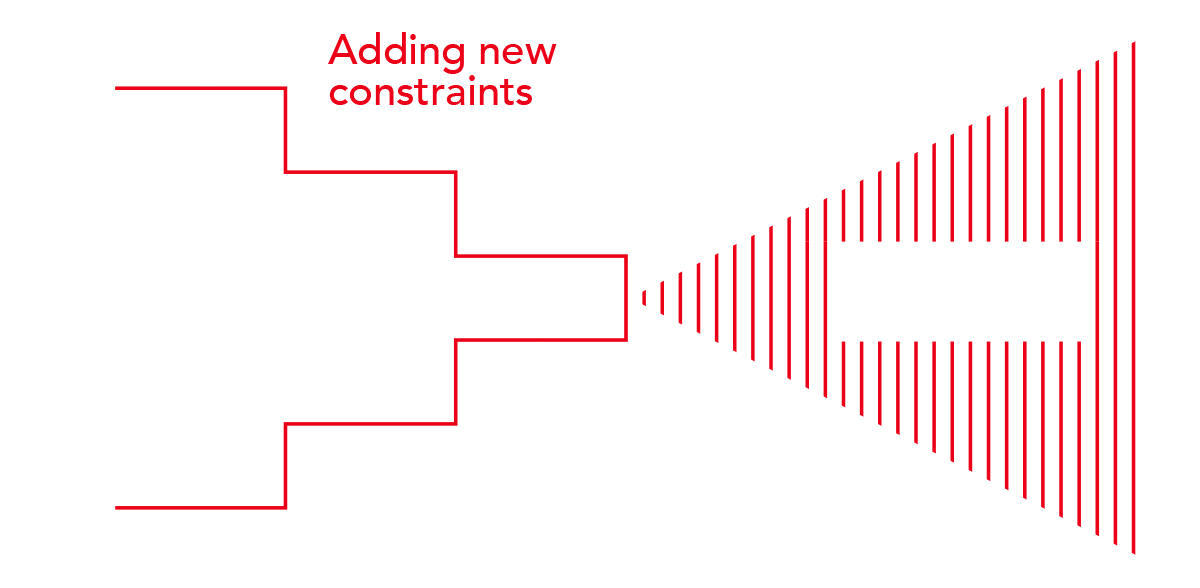

This is the case of one of our clients, yet it is also the situation of many others. These eco-design practices didn’t work because the team had started solving the problem with a mono-parameter approach. They went from replacing an old material with a new one to redesigning with constraints (design-to-cost, on top of a new type of material). With constraints upon constraints, the solution space ends up being empty.

Here’s another example. The innovation team of this multinational cosmetics company wants to reduce the amount of raw material used in their creme containers. The newly-designed concept was not accepted by their brands, as the new containers are much lighter and hence, do not give a luxurious feel to the product. Finding the perfect compromise between environmental friendliness (removing raw materials) and a luxurious feel (adding more raw materials) seems to be a puzzle that is almost impossible to solve.

This dilemma has been occurring more often than not. Despite its good intentions, eco-design as used today, in most cases, often leads to unsatisfying solutions. The problem here is that teams approach a design problem with narrow-defined design parameters: “which material is more “sustainable?”, “how to reduce the amount of raw material used?”... while trying to fit these new concepts into the current systems - the same business models, the same codes of consumption, the same stakeholders with the same needs and demands.

What is the eco-design of tomorrow?

To break free from this limitation of current eco-design practices, it is important to opt for the mindset of designing to reinvent. Let’s take the example of our other client in the cosmetic industry, who also wished to reduce the weight of the containers, hence the amount of raw material. Instead of directly trying to solve this problem using narrowly-defined design parameters, we opted for an extensive exploration of possible concepts. Any characteristic of the current design can be challenged: the shape, the way users interact with the container, the traditional elements, the way these containers are stocked and transported and most important of all, the values perceived by end users. It was necessary to challenge the codes of luxe: less doesn’t mean low-cost, cheap-looking products. Simplicity can be luxurious, purity can also mean lush and desirable.

With this new code of luxe introduced, the company has created a new system, in which a lighter, “purer” cosmetic container can be possible and perceived as desirable by the clients.

Here’s another example to illustrate this mindset of designing to reinvent. The Innovation team of this international premium pet food manufacturer called for us with a clear mission: creating radically new products that allow a reduction of 80% of the environmental footprint.

To reach such a high ambition, the team was ready to challenge the whole system (i.e. products, processes, consumer habits and upstream supply chain). The exploration resulted in 3 concepts allowing a 50 to 80% reduction of the environmental footprint, each with descriptions of their completely different business models, value propositions and production techniques. These 3 concepts are being tested and validated to replace the existing products and processes by 2030

If we had started the project by applying the current mindset of reducing and replacing, we would have gotten stuck with impossible solutions, incompatible with current systems and therefore would never get to the development phase. The change of mindset is critical: from a very narrow set of design parameters such as reducing and replacing, towards a broader ambition of designing to reinvent, in which possible, sustainable and desirable solutions can be allowed to happen.

Conclusion

Business leaders today are being asked from all fronts - regulations, shareholders and clients - to develop more sustainable offers. Therefore, it is essential to get rid of the mono-parameter approach only related to the environmental dimension when it comes to the design and development of new sustainable systems and adopt the design to reinvent mindset.

This mindset can bring out incredible differentiation and game-changing opportunities. Companies, in this case, don’t just aim at doing slightly better than their competitors by optimising some elements of the current system but create an entirely new set of codes and systems, ones that are more desirable and will become the industry’s new standards.

Future Thought Leaders is a democratic space presenting the thoughts and opinions of rising Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.