Why plug-in hybrids (PEVs) are better for the climate than full Electric Vehicles (BEVs) today

· 7 min read

💡 This article is featured in The Definitive Reading List: illuminem’s Recommended Sustainability Classics

I recently came across Toyota’s claim that the critical minerals needed to make a single-battery electric vehicle (BEV) could be used instead to manufacture 6 plug-in hybrid electric vehicles (PHEVs) or 90 hybrid vehicles, which would save much more emissions over the vehicle lifetimes than the one BEV. Could this be true or is this a misleading claim by a company that has fallen behind in the EV race?

There is a broad understanding that EVs face three main challenges in the next decade:

All of these issues are expected to be resolved in the long term as new mineral production comes online (increasingly powered by clean energy) and new battery chemistries go into production, while grid emissions continue to trend down with more solar and wind energy supported by utility-scale batteries.

But the short term is a different story. How should we think about the relative climate benefits of BEVs, PHEVs and even non-plugin hybrids? As a long-time practitioner of life-cycle assessment (LCA), I can’t imagine a better method than LCAs to help answer this question.

The simple LCA that I put together uses an internal combustion engine vehicle (ICEV) as a baseline and looks at the relative benefits of switching to a BEV or a PHEV using a range of electric grid emissions in the US and accounting for the grid gradually becoming cleaner between now and 2035. My goal was to create a framework to better inform policies and purchasing decisions that can drive emission reductions as much as possible by 2035.

All vehicles are assumed to be midsized cars manufactured today and driven in the US for 125,000 miles (200,000 km) between now and 2035. The global battery supply chain is assumed to be dominated currently by China based on IEA’s 2022 Global EV Outlook. Grid emissions make a big difference, so the LCA looks at three distinct cases: the US, California (CA), and the US Midwest (MW) averages. CA represents the lower end of the grid emissions spectrum within the US while MW is near the high end. Grid emission factors represent annual averages in each region.

The details of the LCA are here in a spreadsheet for anyone interested in digging into the details. The results are consistent with the comparative LCA published by the IEA, but customized for US regions and using a realistic upper bound for the emissions from battery mineral production.

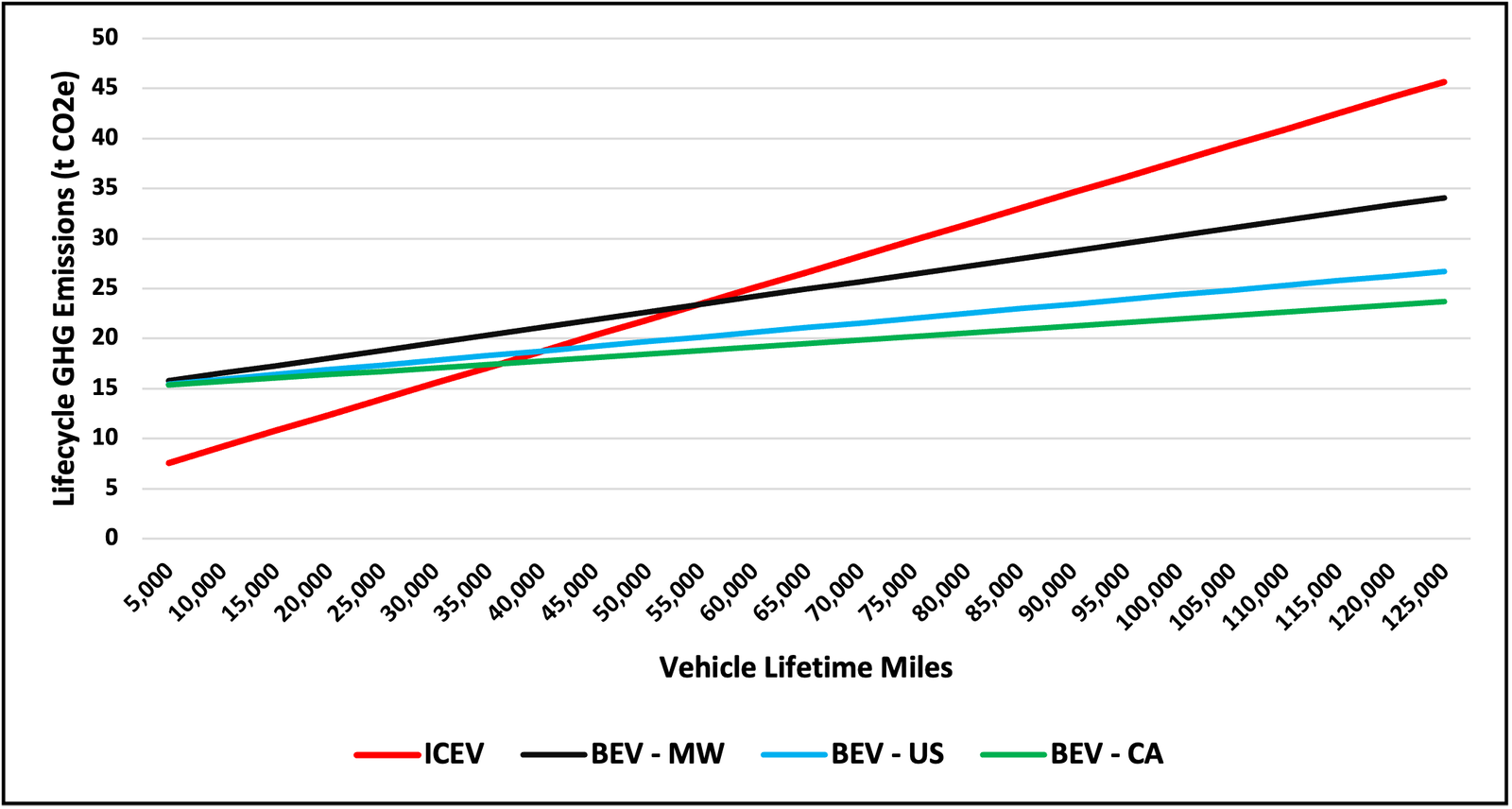

I have captured the key results from the LCA in four charts. Figure 1 below shows that you would have to drive a BEV between 35,000 and 55,000 miles in the US just to reach breakeven emissions against an ICEV. This is mainly because of the higher embodied carbon in the lithium-ion battery (either NCM or LFP battery chemistry) from the production of minerals and battery assembly which are largely powered by fossil fuels in current-generation batteries. This “carbon debt” must be paid off before we see any benefit from the BEV.

The other reason is that the electric grid still depends on fossil fuels like coal and natural gas to generate about 60% of the electricity today in the US, which is expected to drop to 30% by 2035. Over a vehicle's lifetime of 125,000 miles over a period of 12+ years, the BEV reduces emissions by 41% (US average) compared to a gasoline-powered vehicle after considering the expected improvements in grid emissions in that period.

Figure 1. BEV vs ICEV, lifecycle GHG emissions comparison

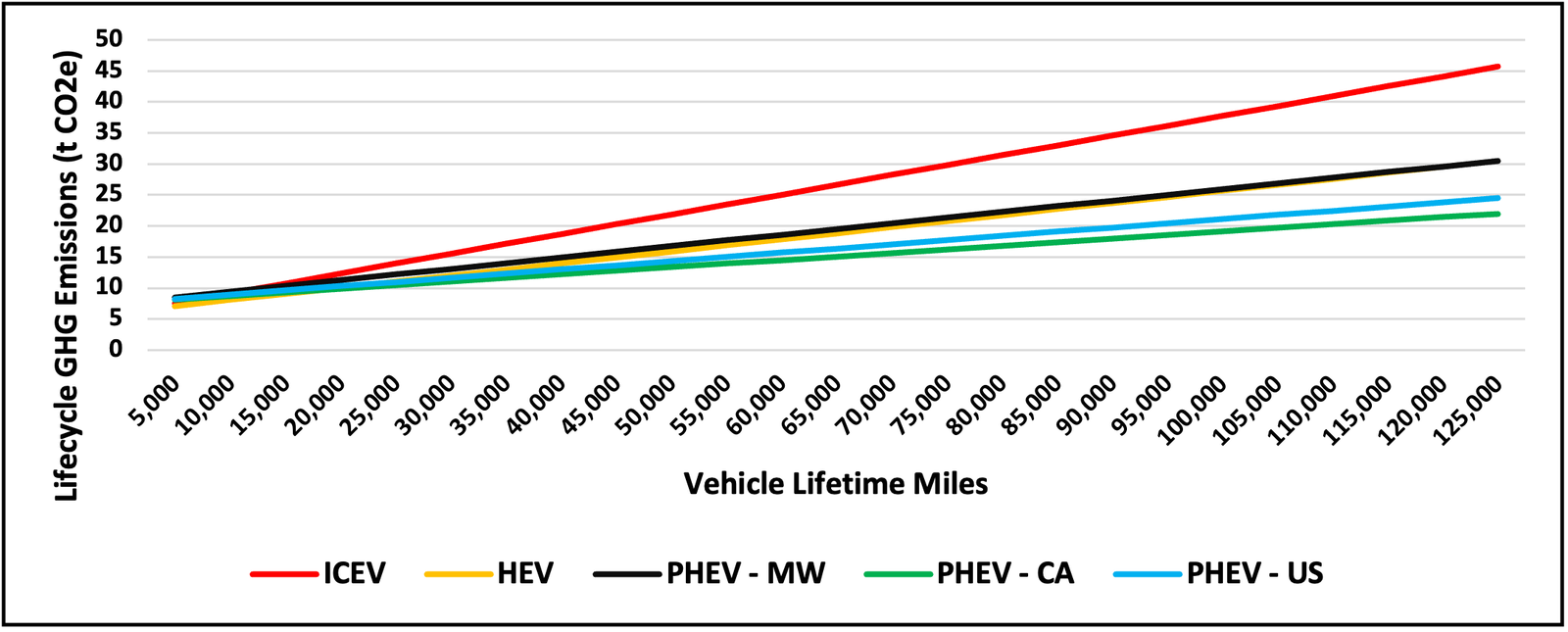

Figure 2 similarly compares a PHEV against both a non-plugin hybrid electric vehicle (HEV) and an ICEV. Breakeven against the ICEV happens at between 10,000 and 15,000 miles, much sooner than with a BEV. A midsized PHEV has a battery size that’s just one-sixth of a BEV’s (Toyota is correct on that point), so the emissions from battery production are also roughly one-sixth. The PHEV still uses grid power, and the analysis here assumes that it uses gasoline for 30% of the miles driven.

Even with that much fossil fuel in the use phase, the PHEV reduces lifetime emissions by 46% on average in the US -- slightly better performance than the BEV with a much lower dependence on critical minerals. The smaller battery and the hybrid technology make a big difference. The PHEV also largely beats the HEV on cutting emissions and the two are about even in the MW region where the grid emissions are high.

Figure 2. PHEV vs HEV vs ICEV, lifecycle GHG emissions comparison

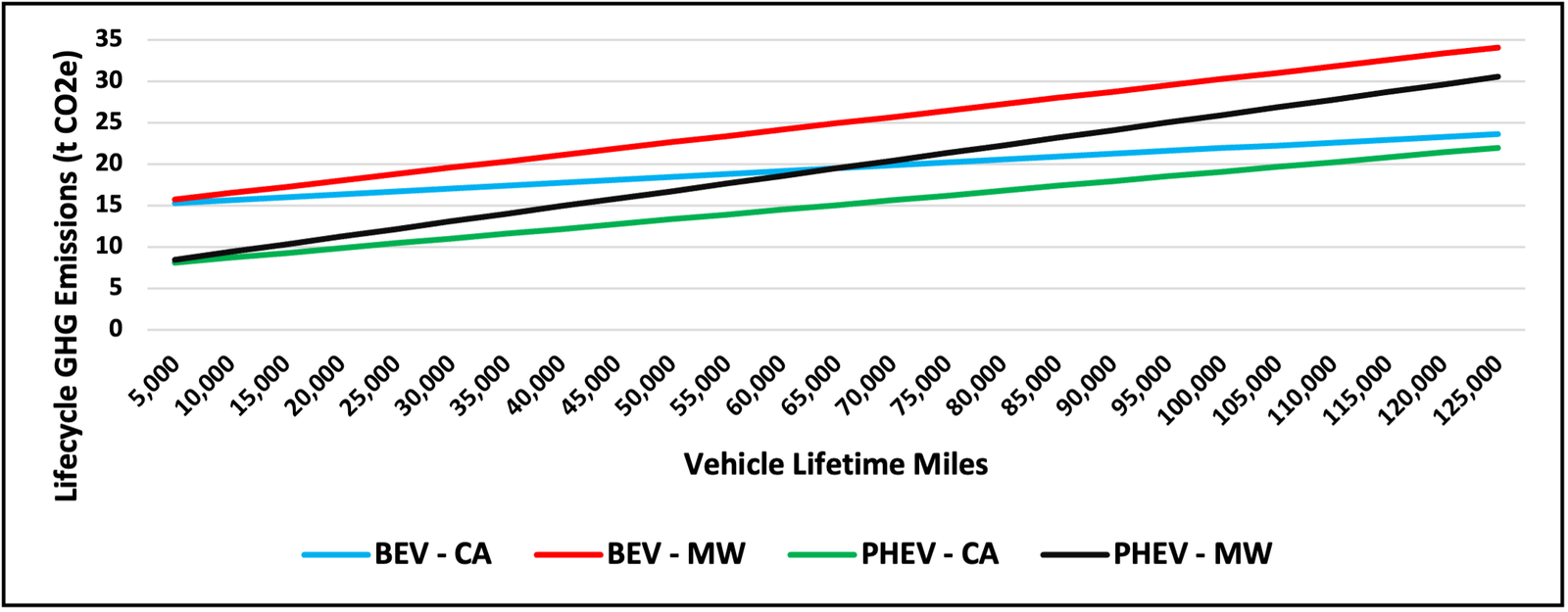

Figure 3 shows that PHEVs are simply better for climate than BEVs across the grid emissions spectrum and at every stage of the product lifecycle. BEVs begin to narrow the difference as the lifetime mileage increases but never reach parity with PHEVs within the 125,000 miles considered here. It is very difficult to work off the high embodied carbon in battery production when the use phase is powered by a grid that is still in a slow transition to clean energy.

Figure 3. PHEV vs BEV, lifecycle GHG emissions comparison

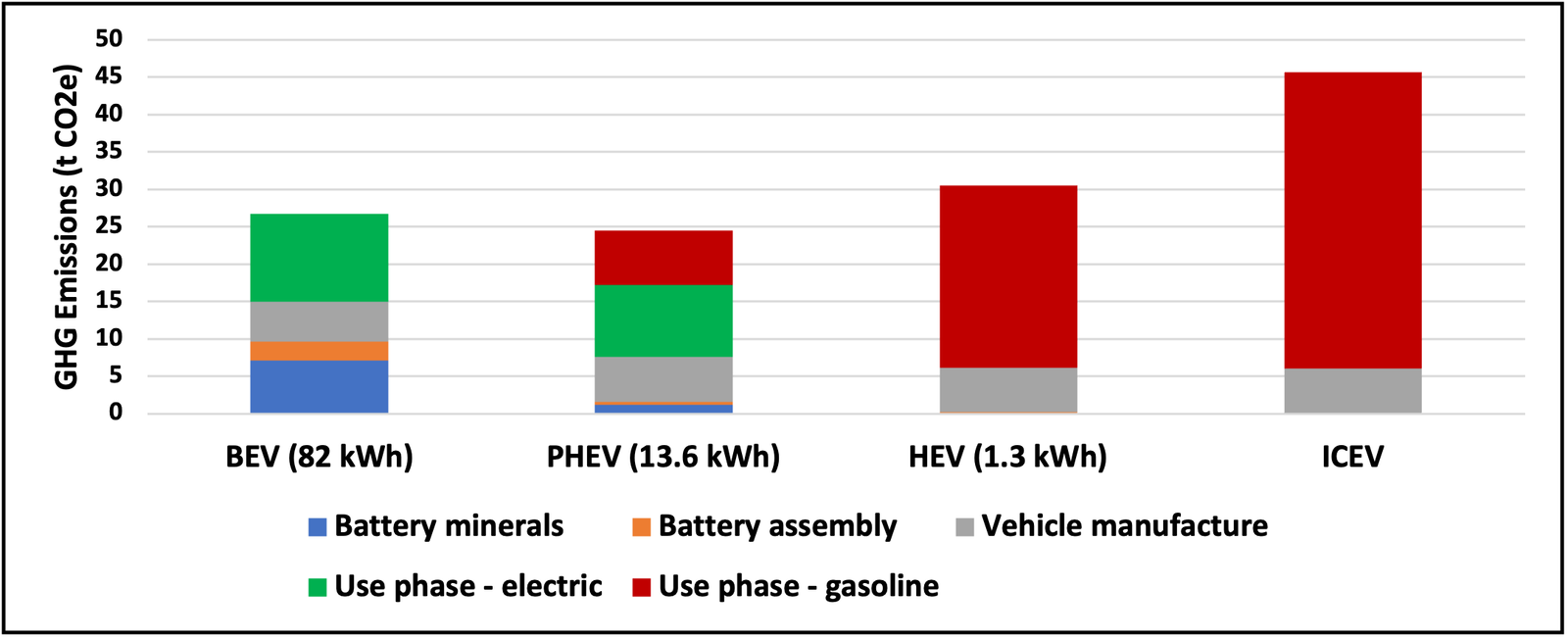

Figure 4 breaks down the lifecycle emissions of the different technologies at the full 125,000 miles. While the use phase has traditionally dominated automobile emissions, BEVs reverse this trend by emitting 56% of their total lifecycle emissions during production. Mineral production and battery manufacture are holding back BEVs from realizing their full potential at present. It is worth noting that the results presented here could of course move around as the underlying assumptions in the LCA change but should nevertheless be directionally correct when comparing current vehicle technologies.

Figure 4. All vehicle technologies, lifecycle GHG emissions breakdown at 125,000 miles

A new report from the Energy Transitions Commission concludes that, even with increased utilization rates and operating efficiency, up to 250 new mines could be required to meet the demand for critical minerals by 2030. Graphite, cobalt, lithium, and neodymium are the primary minerals that are likely to see supply constraints by then unless new production comes online rapidly. Recycling will not play a key role this decade because the number of EV batteries and similar products reaching their end of life will be relatively small compared to the demand for raw materials.

This tells us that we must treat critical minerals as a finite resource in the short term, at least through 2035, and think in terms of extracting the maximum climate benefit from each kg of minerals. This means smaller battery sizes and, in a rational world, a larger role for PHEVs. The longer term is less of a concern: known mineral deposits exceed the total projected demand for both energy transition and other uses through 2050, and technology will likely evolve well before we hit that date.

While the electrification of personal transport is necessary to get to net zero emissions by 2050, we could easily make the transition much harder by racing towards 100% electrification before we have sufficiently expanded, diversified, and cleaned up the mineral supply chains. A lifecycle perspective of transport solutions would suggest that electrification should be done in alignment with projected improvements in battery production as well as clean power generation. PHEVs are a logical intermediate technology in this transition that can deliver better climate benefits today while using critical resources more efficiently.

illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.

illuminem briefings

Electric Vehicles · Green Tech

illuminem briefings

Electric Vehicles · Public Governance

illuminem briefings

Social Responsibility · Sustainable Mobility

The Guardian

Electric Vehicles · Public Governance

The Washington Post

Electric Vehicles · Public Governance

The Wall Street Journal

Green Tech · Mobility Tech