What is sustainable sourcing?

· 8 min read

How can you use data analytics to select the best suppliers considering indicators for sustainability and social indicators?

Sustainable sourcing is the process of integrating social, ethical and environmental performance factors when selecting suppliers.

This involves assessing and evaluating suppliers based on a set of sustainability criteria, such as labour rights, health and safety, environmental impact, human rights, and more.

Assessment of Suppliers based on Environmental Factors — (Image by Author)

The aim is to minimize the negative impacts on the environment and maximize the positive social impacts.

Once you established measurable sustainability targets, you can use data analytics to assess suppliers' performances to select the best one to optimize your objective (cost reduction, CO2 emissions) while respecting social and environmental constraints.

Use data analytics to automatically select the best supplier with a mix of economic and environmental constraints

In this article, we will discover how to use data analytics to design an optimal Supply Chain Network to minimize costs and environmental impacts.

Let us take the example used in the previous articles about life cycle assessment and circular economy.

You are a logistic performance manager in an international clothing group that has stores all around the world.

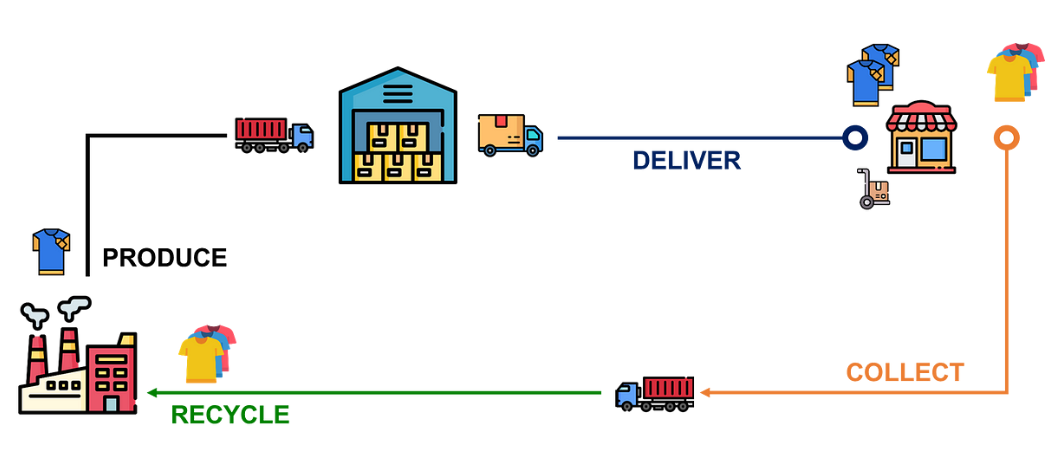

Fast Fashion Company Circular Economy — (Image by Author)

The company is sourcing garments, bags and accessories from factories located in Asia.

Stores are delivered from local warehouses that are directly replenished by factories.

How can you select t-shirt suppliers to minimize your costs while respecting environmental and social constraints?

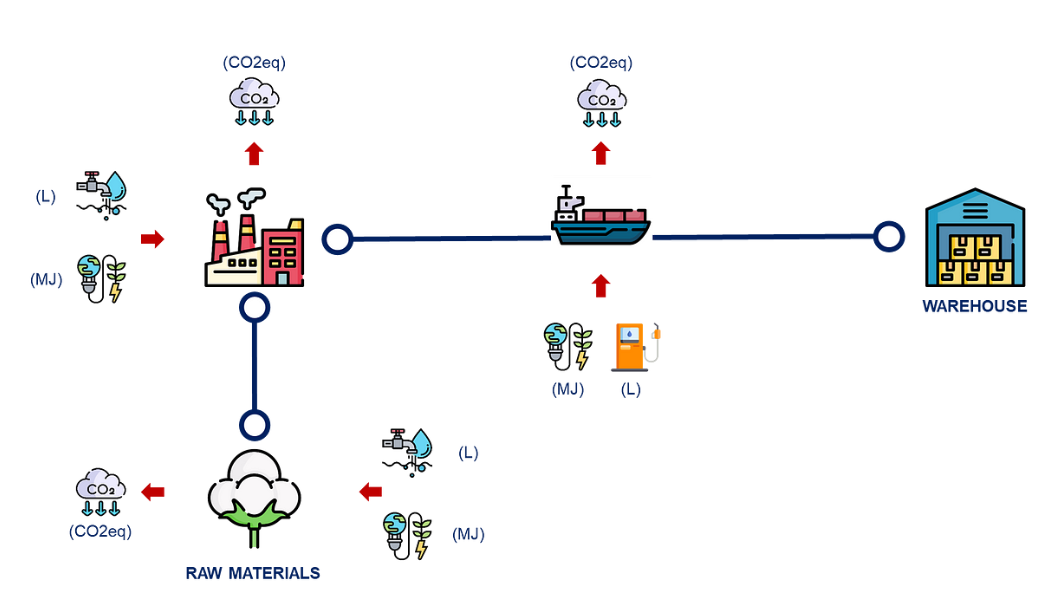

Life Cycle Assessment of Sourcing from Raw Materials to Warehouse Delivery — (Image by Author)

The major indicator that will drive your sustainability roadmap is the carbon footprint of the supply chain.

This can be measured by calculating the total emissions of greenhouse gases such as carbon dioxide, methane, and nitrous oxide.

💡 What should we consider?

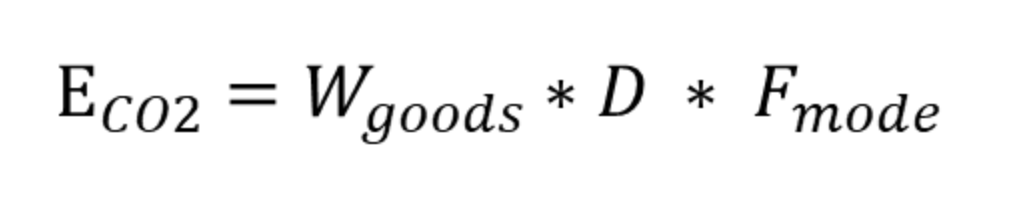

Formula using Emission Factor for Transportation — (Image by Author)

With,

E_CO2: emissions in kilograms of CO2 equivalent (kgCO2eq)

W_goods: weight of the goods (Ton)

D: distance from your warehouse to the final destination(km)

F_mode: emissions factor for each transportation mode (kgCO2eq/t.km)

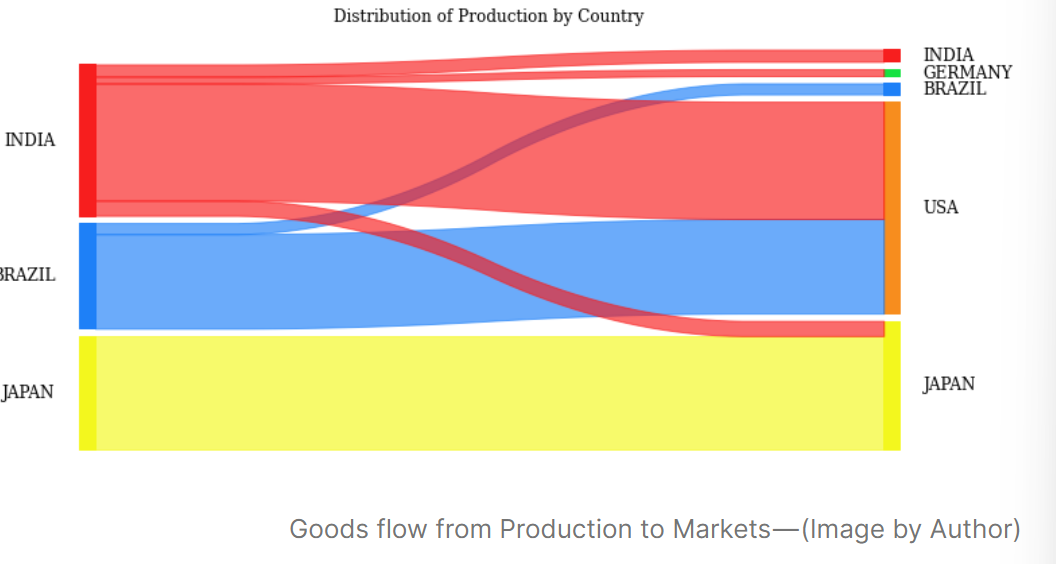

Another indicator is the amount of energy consumed by the supplier to produce and deliver products.

It can be measured in terms of the amount of energy used per production unit (called functional units in the Life Cycle Assessment Methodology).

💡 What should we consider?

As it becomes a scarce resource, new regulations are pushing companies to redesign their processes for water consumption reduction.

With this indicator, you can constrain your sourcing and focus on suppliers that do not affect the local water supply.

💡 What should we consider?

Measuring the amount of waste generated during the production process can help identify areas where waste can be reduced and where more sustainable production methods can be adopted.

💡 What should we consider?

📊 How to organize data collection?

If you are a supplier and you need to provide this kind of reporting you can get the support of data analytics tools to automate it.

Data Lake for Reporting — (Image by Author)

A data lake can be used as a central source of unstructured and structured data (databases, excel files, …).

You can implement automated pipelines to extract, process and analyze these data to build reports and provide insights.

They include indicators for labour rights, fair pay, and safe working conditions to assess suppliers’ performance in terms of social sustainability.

You can conduct your own audits or use third-party assessments.

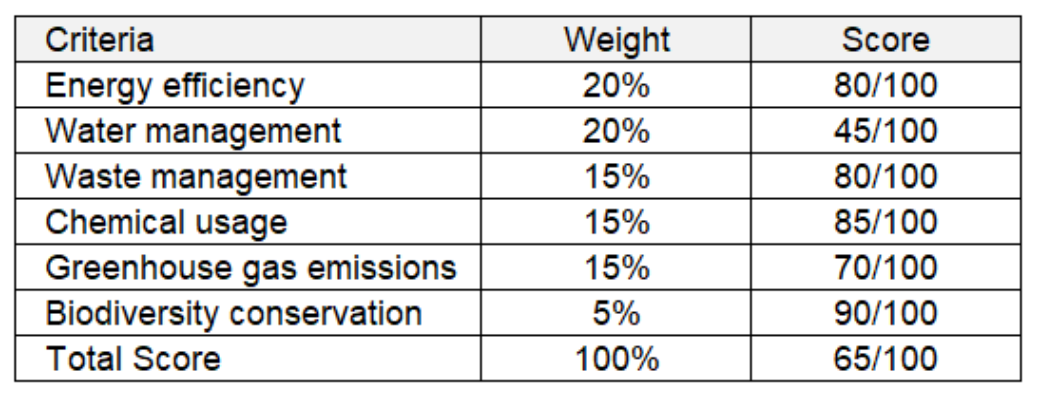

The auditors calculate a score linked to each criterion to represent the supplier’s performance.

The total score is calculated by multiplying each criteria’s score by its weight and summing the results.

They are used to assess if your suppliers are meeting environmental standards focusing on energy efficiency, resource management, chemical usage and greenhouse gas emissions.

💡 How to Measure it?

A similar methodology can be used with the help of a scorecard.

Example of Score Cards vione ards — (Image by Author)

You can get support from governmental agencies and get checklists to support you in assessing the score for each criterion.

At this stage, you have collected information about your suppliers and performed audits with scoring.

You are now ready to use this data to drive decisions, design sourcing and logistics networks to deliver your stores.

Supplier Selection Process — (Image by Author)

We will use an example with dummy data to understand how to implement a data-driven methodology to select your suppliers considering environmental factors.

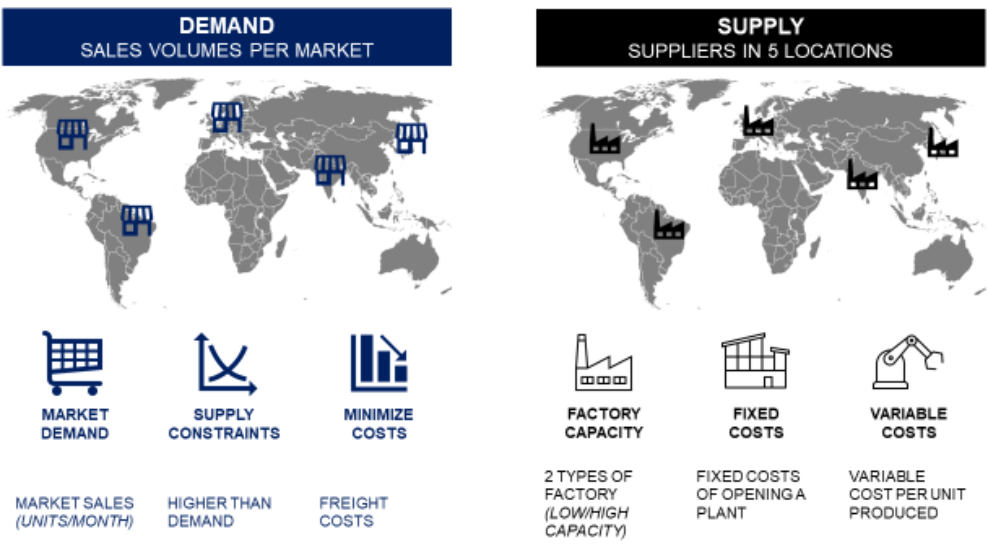

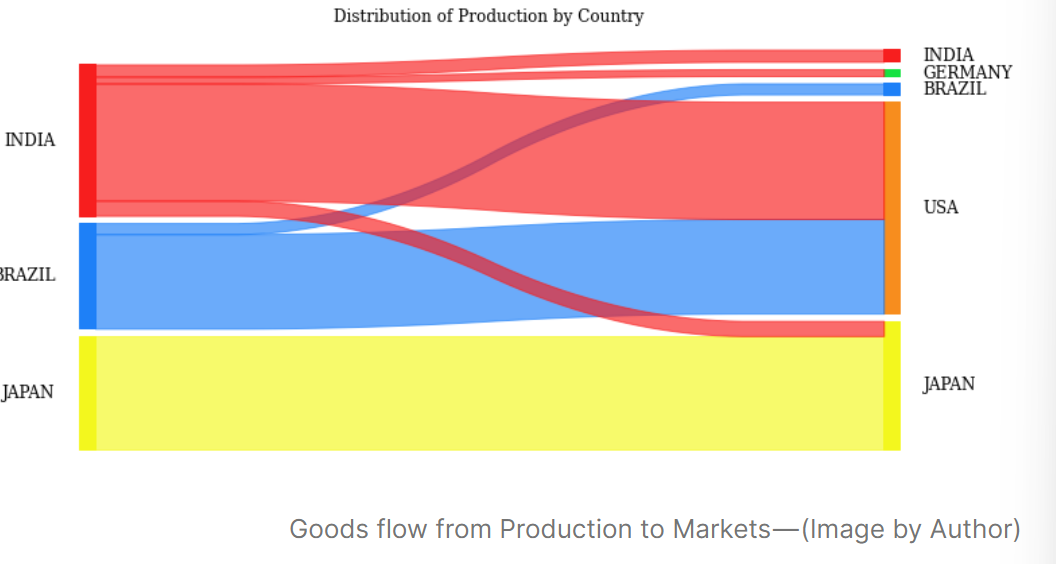

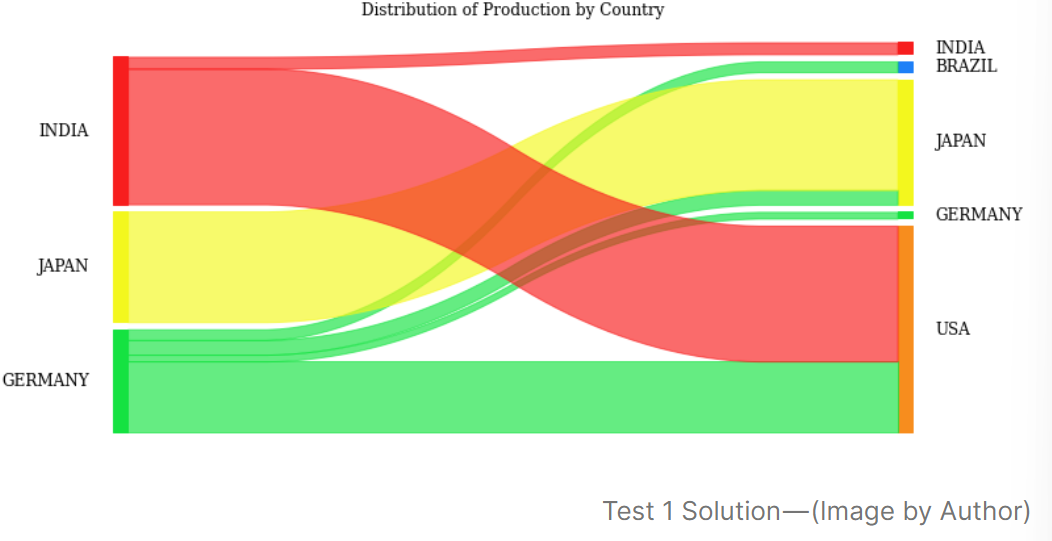

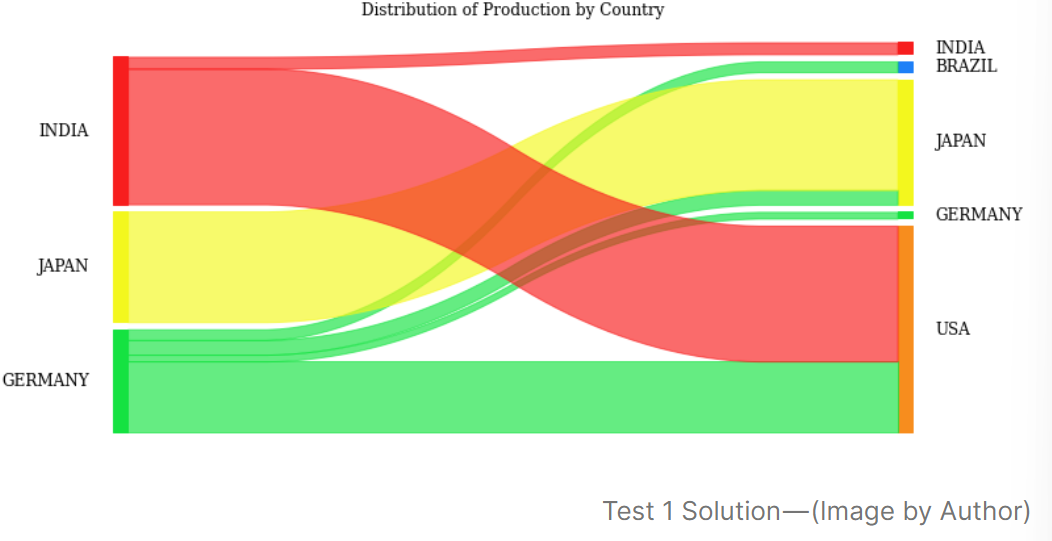

You want to redefine the Supply Chain Network of your fast fashion retail company for the next 5 years.

You have stores in 5 different markets around the world (USA, Germany, Japan, India and Brazil).

In each market, you can select a supplier to produce your t-shirts and you have the choice to source from abroad.

Suppliers Network Design — (Image by Author)

You would like to select the right set of suppliers to minimize the cost of production and delivery considering

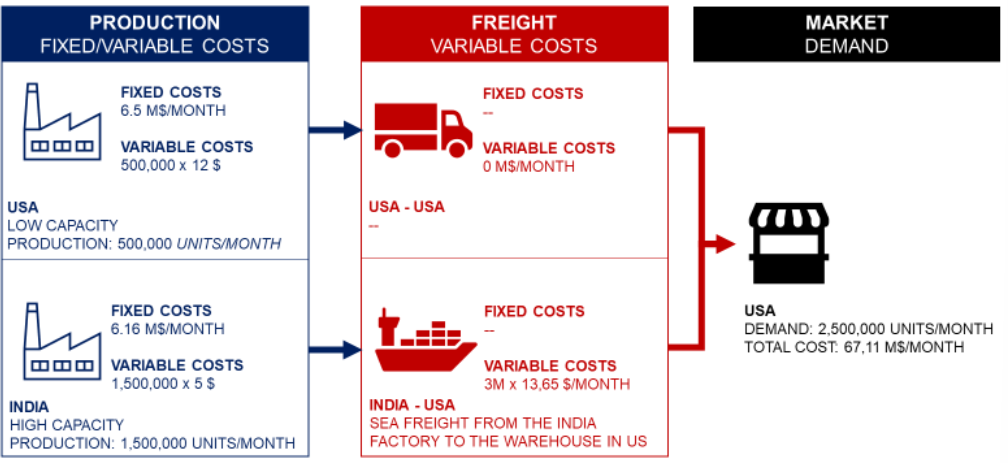

Total cost of production and delivery — (Image by Author)

Your overseas suppliers are cheaper but you need to pay high freight costs to deliver to your market.

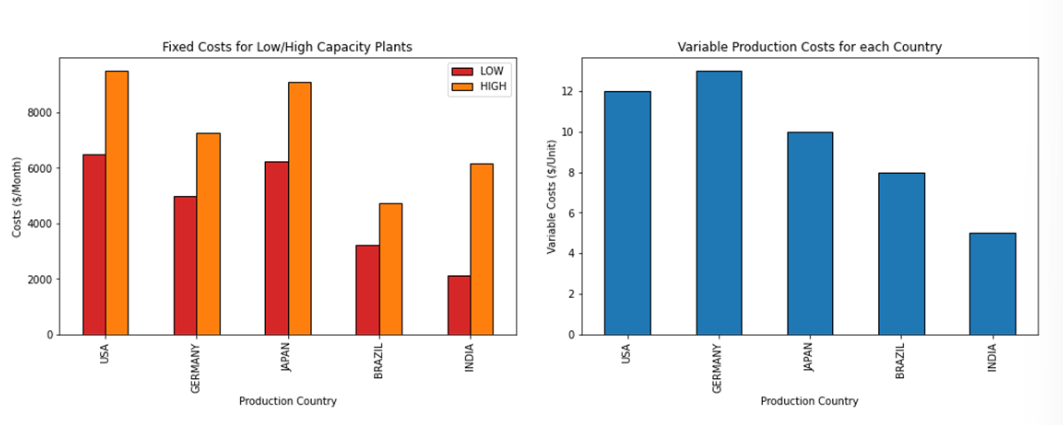

Fixed & Variable Costs by Country of Production — (Image by Author)

Therefore, you need the support of linear programming to make the tradeoff for outsourcing.

If you define the objective function to minimize the costs, you can easily guess that it will maximize the volume produced in India and Brazil.

💡 Insights

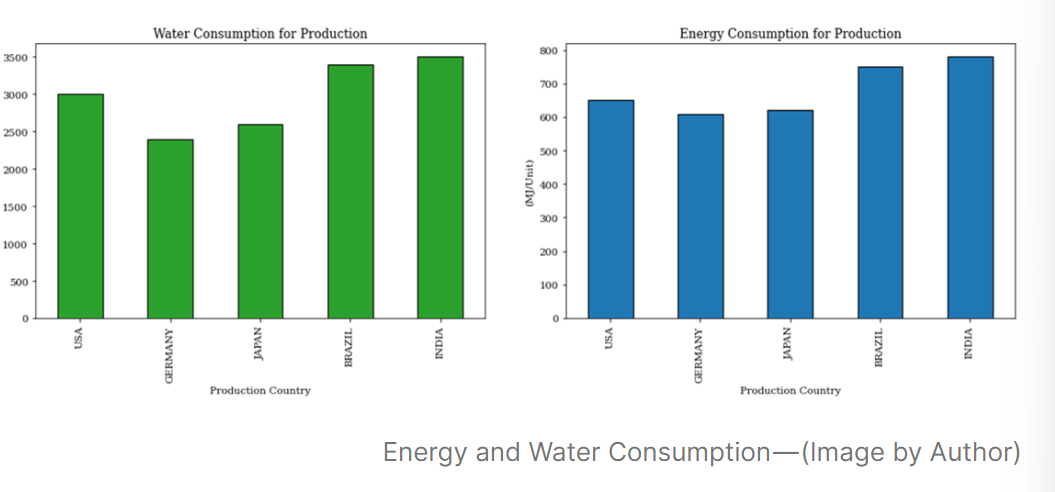

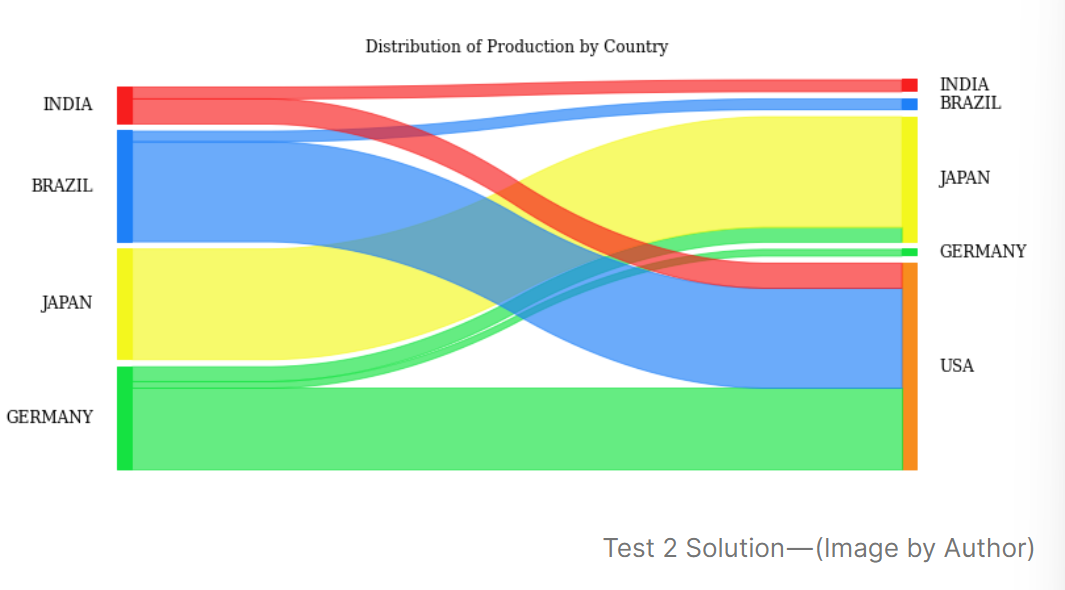

In the context of green transformation, your company is implementing a sustainability roadmap to reduce the environmental impacts of your supply chain.

Therefore, your procurement team has contacted local suppliers in your predominant markets (USA, Japan).

The idea is to redesign the network of suppliers considering

What would be the impact on your sourcing network?

Let us experiment what would be the impact of implementing constraints on the average consumption of energy and water per unit produced.

Your suppliers in Germany and Japan have invested to reduce the environmental impact of their operations.

You would like to add the following constraints

💡 Insights

Transportation accounts for a large part of the CO2 footprint of your Supply Chain.

Therefore, you would like to reduce the impact of upstream flows by limiting the CO2 emissions of

💡 Insights

You can easily add constraints in your model of supplier selection to apply your green transformation initiatives.

In our example, we can see that CO2 emissions constraints can lead to a localization (quasi-localization) of the production to reduce the impact of transportation.

As you can expect, these additional constraints have an impact on the total costs of production.

These results can trigger strategic discussions to find the right balance between sustainable sourcing and cost reduction.

This article is also published on the author's blog. illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.

illuminem briefings

Climate Change · Effects

Kasper Benjamin Reimer Bjørkskov

Degrowth · Regeneration

illuminem briefings

Biodiversity · Sustainable Lifestyle

Al Jazeera

Effects · Climate Change

Forbes

Sustainable Living · Climate Change

Nikkei Asia

Carbon Market · Carbon