· 7 min read

• The North Sea's ageing oil and gas infrastructure requires a multibillion-pound decommissioning effort, posing financial and regulatory challenges

• Effective data management, particularly through Master Data Management (MDM) and standardisation, is key to streamlining decommissioning processes and minimising costs

• Digital tools and structured data enhance efficiency, sustainability, and compliance, transforming decommissioning from a costly burden into an opportunity

The North Sea has been referred to as a cradle of offshore energy innovation, but as its once-vital oil and gas infrastructure ages, a new challenge looms: decommissioning. According to the 2024 OEUK Decommissioning Report, the scale of this task is staggering—the UK Continental Shelf (UKCS) alone will require the decommissioning of over 2,500 wells, representing a multibillion-pound effort in coming decades. As operators face mounting regulatory and public pressures to dismantle these assets – on time and sustainably without huge compromise to their assets’ lifecycle returns on investment –effective data management emerges as the solution to this decommissioning paradox.

The decommissioning paradox: balancing cost and compliance

Decommissioning is an inevitable phase in the lifecycle of offshore infrastructure. However, it is often seen as a financial sinkhole, draining resources without generating revenue. Owner-operators are tasked with the conflicting objectives of minimising costs and meeting regulatory requirements.

In other project phases, these things aren’t always at odds and, in fact, can be very much aligned especially as efficiency-enhancing tools are increasingly adopted. But since decommissioning is the end of an asset’s useful life, expenses associated with this mandatory project phase eat into the overall return on investment (ROI) achieved during an asset’s operational life. Further, as is the case in the UKCS, increasing public and government scrutiny with increasingly punitive requirements place demands on timelines and methods that can inflate project costs.

Assets slated for decommissioning are inherently complicated because they are old. Many North Sea platforms were installed decades ago, long before current decommissioning regulations were conceived. This can make careful, responsible dismantling an intricate and expensive undertaking and, frankly, one that stakeholders understandably long to kick into the deep sea.

Data: the missing link in decommissioning

At the heart of the decommissioning challenge lies a data problem. Offshore assets carry decades of operational data, but this information is often fragmented, siloed, or poorly structured. Legacy systems, inconsistent record-keeping, and limited accessibility hinder the ability to make informed decisions. This leads to some serious consequences revolving around increased inefficiencies and risk, which adversely impact decommissioning project execution, making it a heck of a lot more painful than it ought to be.

Poorly organised data, including information that isn’t easily accessible or standardised, impacts coordination, leading to project delays and unexpected cost overruns. Without reliable data, it becomes harder to plan safe decommissioning workflows and to monitor the status and weights of removed components and structures. Further, gaps in data make it difficult to provide transparent audits that may be required to meet regulatory requirements.

To bridge this gap, offshore decommissioning projects stand to benefit hugely from holistic, centralised data systems capable of unlocking actionable insights from the troves of historical information. The most impactful and accessible actionable insights include much more efficient materials management, work package creation and execution, as well as weights and completions management.

Technological innovations driving change

Digital transformation offers the ability to reshape the decommissioning landscape, particularly through tools that prioritise data collection, standardisation, validation, processing and analysis. The most impactful emerging technology in this vein lies Master Data Management (MDM), a system designed to centralise, standardise and govern the vast amounts of data involved in offshore decommissioning projects. By establishing a single source of truth where every piece of information is written in the same language, MDM addresses the inefficiencies and risks that arise from fragmented or poorly managed data, which are often the source of decommissioning roadblocks.

The importance of data standardisation

A key element of effective MDM is data standardisation—ensuring that all data adheres to the desired recognised framework such as ISO 15926 or CFIHOS (Capital Facilities Information HandOver Specification). These standards establish a common language for asset data, enabling consistent structuring and seamless exchange across systems, stakeholders, project phases and even portfolios.

Data standardisation aligns owner-operators with industry best practices and regulatory expectations. This not only future proofs operations, but enables them to capitalise on the most advanced analytics and emerging digital tools, both of which rely on structured and interoperable data to deliver actionable insights.

In an industry as complex and high-stakes as offshore decommissioning, the consistency provided by data standardisation is critical for avoiding costly delays or miscommunications, ensuring compliant, efficient projects with reliable, audit-ready documentation.

How master data management addresses decommissioning challenges

MDM, which includes data standardisation, enables project teams to implement previously inaccessible efficiency enhancing measures that reverse the drain plaguing offshore decommissioning projects. Proper MDM would clear the sight paths, and the highest-impact measures would surface as a result. Such productivity-improving measures would fall into the broader categories of materials management, work packages, weight management and completions.

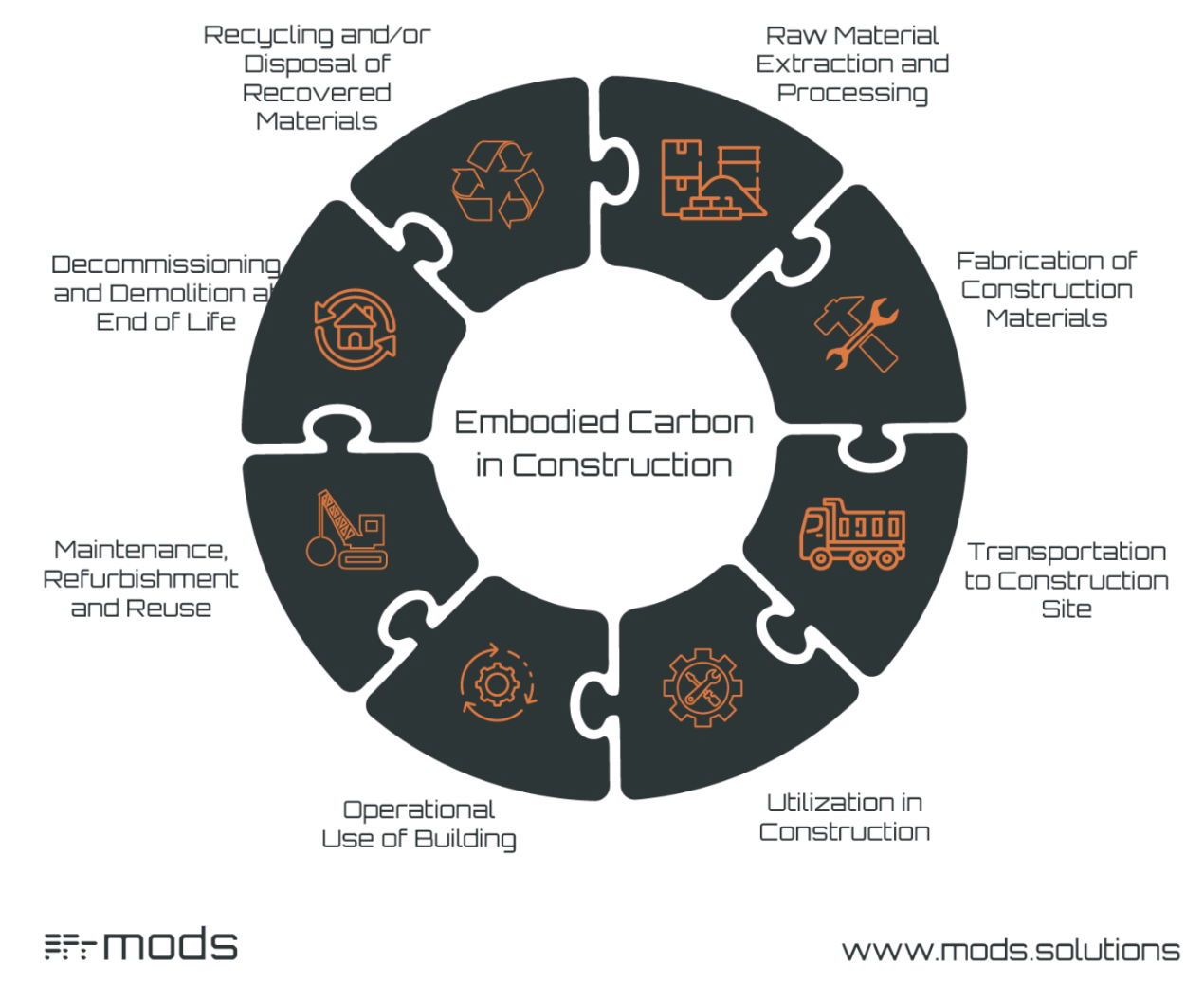

- Materials management: Offshore decommissioning involves handling significant volumes of materials, from reusable equipment to scrap metal. MDM ensures accurate inventory tracking and forecasting, reducing redundancy and waste. When used in tandem with a capable materials management system, standardised data facilitates better identification and classification of materials, enabling opportunities for recycling and reuse, which is essential to enhancing the sustainability of decommissioning.

- Work package creation and execution: The development of work packages often requires reconciling data from multiple sources. Without MDM, this process is prone to delays and errors. A centralised and standardised data framework eliminates these bottlenecks, allowing for faster, more accurate digital work package creation, issuance and execution. Further, real-time updates ensure that all stakeholders operate with the latest information, minimising miscommunication and improving coordination across teams.

- Weight management of removals: Accurate weight data is essential for planning heavy-lift operations and transport logistics, another potential decommissioning bottleneck. When funnelled into completions software, for example, MDM ensures precise weight calculations by integrating and standardising data from various sources. This also reduces safety risks and enhances compliance with regulatory requirements by providing clear, consistent records.

- Completions processes: The final stages of decommissioning require meticulous tracking of milestones, ITRs, punch lists and documentation. MDM ensures that all data is organised and accessible, streamlining completions processes. Standardised and centralised data fed into a digital completions system simplifies audits, reduces disputes and demonstrates compliance more effectively.

Data boosts decommissioning productivity, ROI and sustainability

One of the most tangible benefits of MDM is its ability to improve time-on-tools by ensuring that workers spend less time searching for, verifying, or correcting data. This directly enhances productivity and minimises project delays. By improving coordination and decision-making, MDM also helps decommissioning teams achieve greater efficiency, keeping projects on time and within budget.

From a sustainability perspective, MDM supports more responsible decommissioning practices by enabling better materials management, reducing waste and identifying opportunities for recycling and reuse. These practices align with the industry's growing focus on environmental stewardship and corporate responsibility.

By leveraging the wealth of an aged asset’s data, operators can streamline project execution, reduce costs, and enhance sustainability—transforming decommissioning from a liability into an opportunity.

The future of decommissioning lies at the intersection of cost efficiency, regulatory compliance and environmental sustainability. Data is the thread that weaves these priorities together, enabling operators to tackle the decommissioning paradox head-on.

As the North Sea sets the stage for a global shift, it’s time for the industry to embrace the transformative potential of digitalisation. By adopting robust data systems and innovative technologies, stakeholders can turn decommissioning from a financial sinkhole into a sustainably managed necessity.

illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.