· 6 min read

A crossroads for WtE and CCUS: redefining sustainability in the UK

The UK’s Ten Point Plan for a Green Industrial Revolution boldly aspirates for a cleaner future. Carbon Capture, Utilisation, and Storage (CCUS) is critical in delivering this aspiration. The East Coast Cluster stands in the vanguard of this ambitious strategy, aiming to remove nearly 50% of the UK’s industrial cluster emissions and support an average of 25,000 green jobs annually between now and 2050. While most of the current CCUS projects focus on low-carbon power generation or hydrogen supply, another promising pairing can contribute to delivering the net zero aspirations. Although not prioritised in the UK Government Track-1 CCUS cluster sequencing exercise, integration of waste-to-energy (WtE) and CCUS can deliver negative CO2 emissions and reduce the amount of landfilled waste.

Notably, while WtE offers a valuable waste management solution and generates energy, its contribution to the CO2 emissions in the UK is substantial. In the Teesside Cluster alone, which is a part of the East Coast Cluster, WtE accounts for a staggering 18% of total greenhouse gas emissions. The projections are also concerning, as the UK’s WtE has been forecasted to emit up to 20 MtCO2e annually by the mid-2020s. Such a figure is higher than 11 MtCO2e annually reported in 2021 for industrial processes in the UK. The preliminary work on WtE and CCS integration by the Energy Systems Catapult showed that the specific CO2 emissions from WtE are 600 gCO2/kWh (excluding biogenic carbon), and flue gas contains up to 12%vol CO2. As a result, their ESME model demonstrated that unabated WtEs must be phased out by 2040 due to reduced carbon budgets, indicating the need to develop low-carbon alternatives.

This is where CCUS can play a role. By strategically integrating CCUS into existing WtE plants, the UK can achieve a two-pronged victory: significantly curbing its carbon footprint and transforming WtE into a net negative emitter of greenhouse gases. Yet, unlocking the full potential of WtE-CCUS synergy requires careful consideration. Existing CCUS solutions, while potentially effective in larger-scale applications, pose challenges for WtE due to their high energy demands and potential impact on energy output and profitability. The search for alternative CCUS technologies with lower energy penalties and costs becomes paramount.

Therefore, the future of WtE in the UK's decarbonisation strategy hinges on two pillars: embracing innovation in CCUS technologies tailored to WtE applications and forging strategic partnerships to navigate the technological and economic complexities.

The challenge: decarbonising WtE without hindering energy or economic performance

While amine scrubbing has emerged as the CCUS technology of choice for many industrial applications, such as the Net Zero Teesside Power, its application to WtE presents unique and prohibitive challenges. This mature approach to CO2 capture stumbles on the high demand for steam required for its regeneration. In the UK, WtE plants often play a critical role in supplying heating, electricity, and/or industrial steam. Implementing amine scrubbing can have a detrimental impact on these vital functions, jeopardising both WtE's energy output and economic viability.

The severity of these challenges is well documented. An AECOM study revealed that amine-based capture units could consume a staggering 66% of the total thermal input to the steam turbine at a combustion-based WtE plant. This translates to a significant reduction in electricity generation, a key revenue stream for WtE facilities. Further research by Magnanelli et al. confirmed this concern, demonstrating that amine scrubbing integration can lead to a 30% reduction in power output and a 12% reduction in heat output from a typical WtE plant. Supplying such an amount of steam will not only be limited by technical considerations but will also substantially impair the economic viability of the WtE plant.

Adding to the complexity is the lack of readily available information regarding post-combustion CO2 capture for gasification-based WtE plants. These facilities, utilising a different waste processing technology, present additional unknowns regarding CCUS compatibility. This knowledge gap further accentuates the need for alternative CCUS solutions that can overcome the limitations of amine scrubbing and effectively decarbonise WtE without compromising its energy production and economic viability.

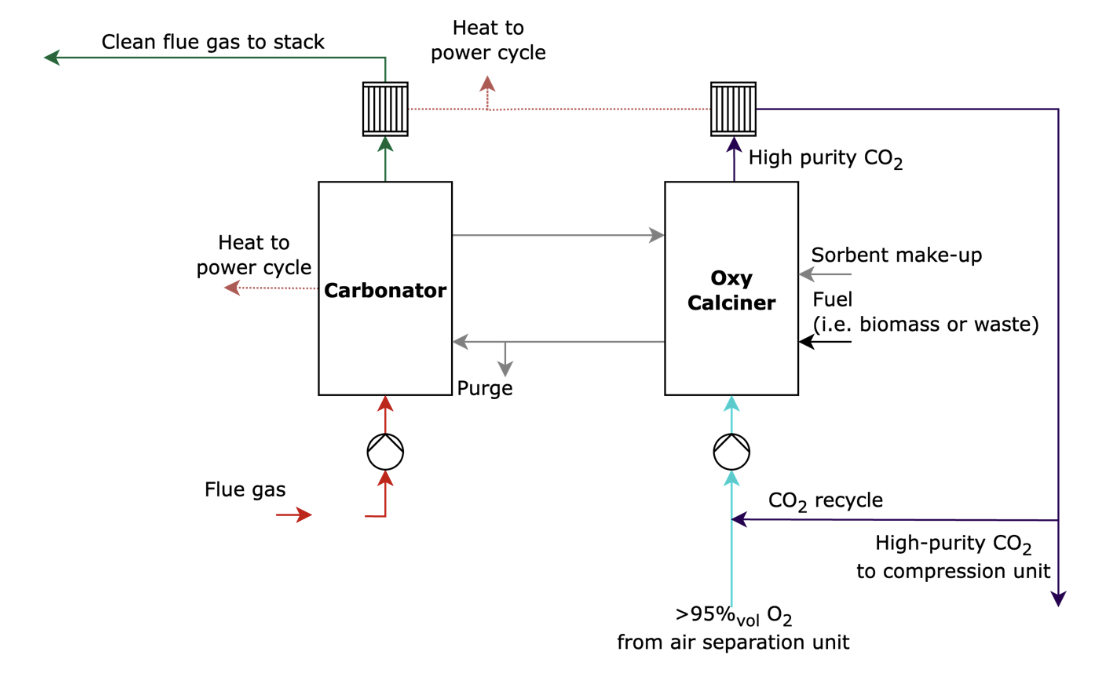

A promising solution: exploring the potential of carbonate looping

Amidst the challenges of WtE decarbonisation with mature amine scrubbing, our research at the Net Zero Industry Innovation Centre has focused on emerging carbonate looping (CaL) technology. Unlike steam-hungry amine scrubbing, CaL offers a potentially cost-effective and energy-efficient solution for capturing CO2 from WtEs. Our past studies have demonstrated the remarkable cost advantages of CaL. Hanak et al. revealed that post-combustion CaL retrofits to coal-fired power plants could achieve a competitive cost of CO2 avoided (~£40/tCO2), significantly lower than the range reported for amine scrubbing by Wood (ranging from £73 to £173/tCO2). This translates to a potential financial incentive for WtE operators considering CO2 capture.

However, the benefits of CaL extend beyond cost savings. Compared to amine scrubbing, CaL exhibits a demonstrably lower impact on energy efficiency (<7% points) and can actually increase the power output by 20-50%. This means that WtE facilities adopting CaL can maintain their current energy generation capabilities while simultaneously capturing CO2.

However, our research pushes the boundaries even further. We have proposed calcium looping combustion (CaLC) as a potential breakthrough technology for WtE decarbonisation. By replacing conventional incinerators with indirect heat transfer in the calciner, CaLC can minimise efficiency penalties to an impressive <3% points. For power generation from coal, our research showed a remarkably low cost of CO2 avoided of <£35/tCO2. Notably, municipal solid waste is a lower-quality fuel than conventional fossil fuels. Therefore, the expected efficiency penalties and cost of CO2 avoided are expected to be higher. Yet we forecast it will still be substantially lower than the mature amine scrubbing retrofits. At NZIIC, we are currently working with the UKCCSRC and the major waste-to-energy organisations in the Teesside Cluster to assess the feasibility of such technology.

Conclusion

As the UK embarks on its Green Industrial Revolution, the East Coast Cluster stands as a beacon of ambition, aiming to capture nearly half of the UK’s industrial emissions. While the focus is low-carbon power and hydrogen, an often-overlooked pairing holds immense potential: integrating Waste-to-Energy (WtE) with Carbon Capture, Utilisation, and Storage (CCUS). Such a synergy offers a two-pronged victory, curbing the nation's carbon footprint and transforming WtE into a net negative emitter.

However, unlocking this potential requires navigating a complex landscape. While effective in larger applications, traditional amine scrubbing proves problematic for WtE due to its high energy demands and detrimental impact on energy output and profitability. The search for alternative CCUS solutions with lower energy penalties and costs becomes paramount.

Our research at the Net Zero Industry Innovation Centre focuses on carbonate looping (CaL) as a promising alternative. Unlike amine scrubbing, CaL presents a cost-effective and energy-efficient solution. Studies indicate a competitive cost of CO2 avoided and minimal efficiency penalties. This allows WtE operators to embrace carbon capture without compromising their core functions.

Acknowledgement: This publication is based on research conducted within the “Techno-economic and carbon footprint assessment of advanced waste-to-energy with carbon capture and storage for East Coast Cluster” project funded by the UK Carbon Capture and Storage Research Community.

illuminem Voices is a democratic space presenting the thoughts and opinions of leading Sustainability & Energy writers, their opinions do not necessarily represent those of illuminem.