· 2 min read

According to many sources globally, it is well understood and accepted that grinding, or comminution, accounts for approximately 53% of a typical mine’s energy consumption. Furthermore, this equates to about 3-4% of global energy consumption. In today’s world of increasing costs for energy and rising inflation, it is more important than ever to address the efficient utilization of energy to produce the raw materials to meet the increasing global demands.

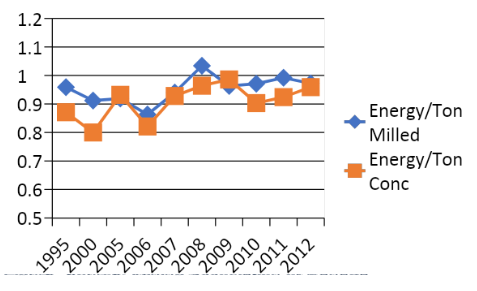

Data from the Mining Association of Canada (Figure 1) shows the trend in energy consumption for milling and concentrate production. Clearly, the upward trend indicates that there are external factors attributing to the growing need. This can be explained by grades within the ore bodies decreasing, harder ores from deeper deposits, complexity of the mineralization, and compliance with ESG regulations.

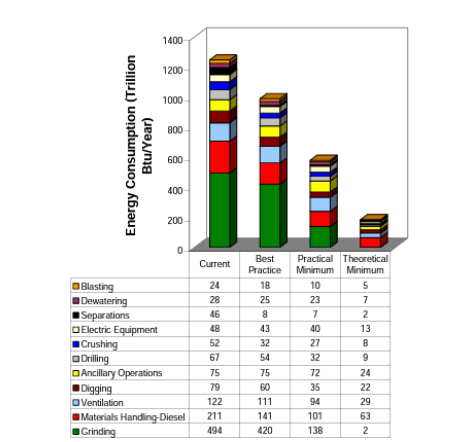

A recent study conducted by the USGS (Figure 2) shows the energy consumption by mining and mineral production operations. For those familiar with the processes involved, it is understood that size reduction for the purposes of liberating the valuable mineral from the host rock is the most energy intensive unit operation. As a result, equipment manufacturers collaborating with mine operators, focus much of their attention on technologies to reduce the energy required per ton.

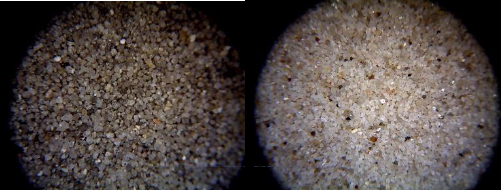

A newly developed ablation-style process (HPSA) that preferentially targets contrasts in mineral hardness and grain boundaries (Figure 3) as a mechanism for liberation. Rather than focusing solely on reduction in particle size, or P80, HPSA focuses on removing the specific mineral particles from the larger particles. Such an approach to liberation is novel from the perspective of targeting the energy to liberation and not comminution, although comminution is a by-product.

HPSA technology shows increasing promise for selective liberation as opposed to more traditional grinding methods, resulting in energy savings for mine operators.

Illuminem Voices is a democratic space presenting the thoughts and opinions of leading Energy & Sustainability writers, their opinions do not necessarily represent those of illuminem.